Catalytic Emission Control

"Research and further development of catalytic processes to abate emissions from combustion processes of biomass energy sources ensures the necessary environmental friendliness of bioenergy."

Prof. Dr. Ingo Hartmann, Head of the research focus area

Objective

The research focus area "Catalytic Emission Control" researches long-term and high-temperature stable, as well as recyclable and cost-effective catalysts without or with significantly lower amounts of noble metals. In particular, the combination of catalysts with additional emission abatement processes will be studied in detail. Therefore, environmentally friendly catalyst syntheses are investigated, which focus on the stability of the catalysts as well as the avoidance of noble metals as active catalyst species.

The research focus area is able to cover the entire development from laboratory to application.

Background

Gaseous, liquid and solid hydrocarbon-containing bioenergy feedstocks are almost invariably converted into thermal energy by combustion. Depending on the bioenergy source and the combustion process, methane (CH4), other volatile organic compounds (NMVOC) but also semi-volatile and low-volatile hydrocarbons such as polycyclic aromatics (PAH) and polychlorinated dioxins and furans (PCDD/PCDF) as well as soot (black carbon) are emitted in relevant quantities, which can cause GHG effects and/or environmental damage due to toxicity. Since 1995, according to data from the German Federal Environment Agency, there has been no decrease in annual emissions of PAHs and PM2.5 from the household energy sector (for 2017: PAHs = 146 633.7 kg/a; PM2.5 = 18.4 Mg/a). This is also due to the increased use of biomass for energy. These figures clearly show that for the thermal use of bioenergy fuels to increase sustainability, emission reduction measures focusing on the air pollutants CO, CH4, NOX, PAH and soot particles (black carbon) need to be further investigated in the future and also demonstrated and introduced to the market under practical conditions. These pollutants can be significantly minimized by catalytic exhaust treatment and integrated processes.

News

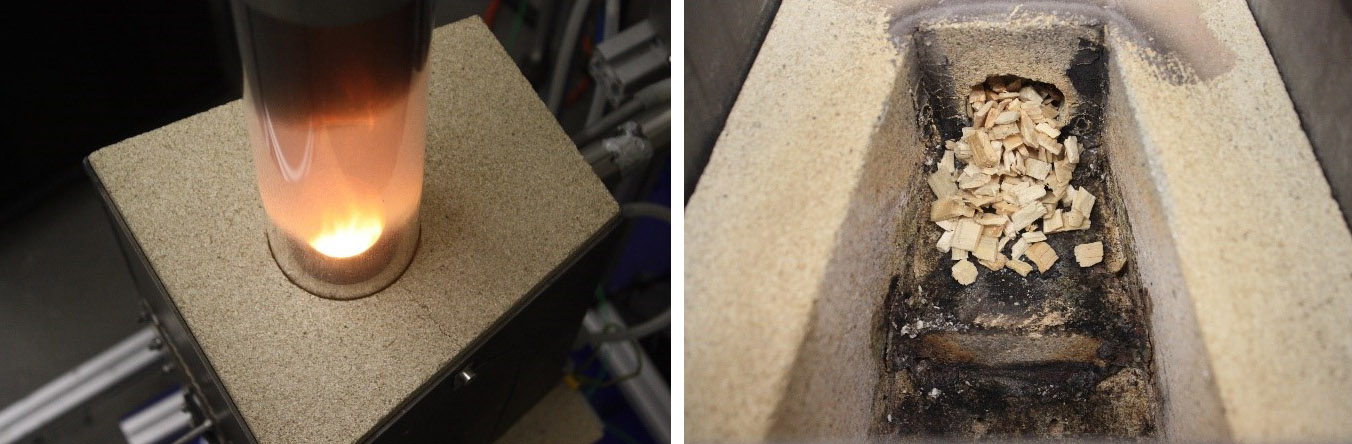

In cooperation with the Technical University of Freiberg, we are currently working on a project to develop and investigate a unit for the fuel-flexible energetic utilization of biogenic residues consisting of a gasifier unit and a catalytic tube bundle reactor. The conversion of solid biomass into fuel gases at the lowest possible temperatures is intended to inhibit the release of mineral components such as potassium from the biomass. Since such substances act as aerosol forming agents, the amount of particulates emitted can be significantly reduced compared to conventional combustion processes. Compared to typical gasifier product gases, the resulting burnable gas contains a larger fraction of hydrocarbons, which need to be completely converted catalytically to CO2 and H2O by total oxidation. In this way, nearly pollutant-free combustion can be realized.

The development of a stove for the combustion of wood chips takes place in cooperation with the Fachhochschule Südwestfalen, the Energie Holz Hess GmbH & Co. KG and the company IBT-Krämer. By now, an analyzation of the fuel conditioning on combustion quality has been carried out with a special designed combustion and fuel supply zone for the use of wood chips. Despite the low nominal heat output of the furnace (below 4 kW), the flue gas concentrations comply with the emission limit values for carbon monoxide and particulate matter from the 1st BImSchV already. During next year further development to a marketable stove is planned in cooperation with stove manufacturer.

The PaCoSil project (project partners: A.P. Bioenergietechnik GmbH and ETE EmTechEngineering GmbH), which started in July 2021 and is funded by the BMWi/PtJ, explores how regenerative heat and additionally coupled silicon enriched porous and X-ray amorphous inorganic solids can be produced with regionally available biogenic residues in Germany in order to make them usable for material use in environmental technology applications. During the material utilization coupled to the heat-controlled production, siliconrich biogenic residues are used as a by-product. The economic feasibility of the project is given particularly by the fact that heat-controlled production can be combined with the material utilization of the ash fractions. The focus of the project is therefore on the energetic utilization of the material and requires a technical development for the process steps to be implemented.

Facilities

An appropriately equipped technical center and characterization laboratory is available for research, which is unique in Europe, especially with regard to application-oriented and near-market applications of catalytic emission control at bioenergy units. The data from the market-oriented research projects are evaluated, published and made available to the public in the form of freely accessible databases.

Based on the competence of the staff, the research focus area together with the technical infrastructure represents an important source for the bioenergy industry for the development and evaluation of emission reduction processes at decentralized energy supply plants in order to establish innovative devices and plant components on the market directly from research in cooperation with companies.

Important reference projects (Selection)

- HypoBio - Energetische Nutzung von Scheitholz durch die Entwicklung einer effizienten und emissionsarmen, kleinen Scheitholzfeuerung mittels kontinuierlicher Brennstoffzuführung, Bundesministerium für Ernährung und Landwirtschaft/Fachagentur Nachwachsende Rohstoffe e. V., 01.08.2020 - 31.07.2022 (FKZ 22033218)

- UVV – Verbundvorhaben: Emissionsminderungsstrategien zur umweltverträglichen Verbrennung (UVV) auf Basis von aktuellen Forschungsergebnissen, Teilvorhaben 1: Theoretische und Experimentelle Untersuchungen, Koordination; Bundesministerium für Ernährung und Landwirtschaft/Fachagentur Nachwachsende Rohstoffe e. V., 01.04.2019 – 31.03.2022 (FKZ: 22038418)

- GASASH – Thermo-chemische Konversion von Reststoffen in einem Vergaser-BHKW mit gekoppelter Aschegewinnung; Teilvorhaben: Untersuchungen zur Produktgasqualität, den BHKW-Emissionen, Emissionsminderungsmaßnahmen und der Ascheverwertung, Bundesministerium für Wirtschaft und Energie/Projektträger Jülich, 01.09.2018 - 30.06.2021 (FKZ: 03KB139A)

- SCRCOAT – Optimierung u. Validierung von Verfahren zur kombinierten Reduktion von Feinstaub und sauren Schadgasen an Biomassefeuerungen; Teilvorhaben: Experimentelle Untersuchungen zur Kombination von SCR- und Precoatverfahren an einem Gewebefilter, Bundesministerium für Wirtschaft und Energie/Projektträger Jülich, 01.09.2017 - 28.02.2021 (FKZ: 03KB128A)

- KaRo – Katalytischer Rohrbündelreaktor für die Totaloxidation von Brenngasen aus der thermischen Umsetzung von festen Biobrennstoffen zur emissionsarmen regenerativen Wärmeerzeugung, Sächsische Aufbaubank, 01.10.2019 - 30.06.2022 (FKZ: 100332481)

Important publications (Selection)

- He, Fang; Li, Xiuhua; Behrendt, Frank; Schliermann, Thomas; Shi, Junrui; Liu, Yongqi (2020): Critical changes of inorganics during combustion of herbaceous biomass displayed in its water soluble fractions. In: Fuel Processing Technology 198. DOI: 10.1016/j.fuproc.2019.106231.

- Stolze, Bettina; Hartmann, Ingo (2020): Zeitliche Darstellung des Alterungsverhaltens eines Oxidationskatalysators in einem Biogas‐BHKW. In: Chemie Ingenieur Technik 92 (6), S. 782–787. DOI: 10.1002/cite.201900152.

- König, Mario; Müller, Mirjam; Hartmann, Ingo (2021): Emission reduction process for the energetic use of biogenic residues. In: IOP Conference Series: Earth and Environmental Science (642). DOI: 10.1088/1755-1315/642/1/012006.

- Formann, Steffi; Hahn, Alena; Janke, Leandro; Stinner, Walter; Sträuber, Heike; Logrono, Washington; Nikolausz, Marcell (2020): Beyond sugar and ethanol production. Value generation opportunities through sugarcane residues. In: Frontiers in Energy Research 8. DOI: 10.3389/fenrg.2020.579577.

- Hartmann, Ingo; Tebert, Christian (2020): The new Blue Angel ecolabel certification method for firewood stoves. 6. Central European Biomass Conference. Graz (Österreich), 22.01.2020.