Pilot plant for renewable methane

The pilot plant, which was built at the Deutschen Biomasseforschungszentrum gemeinnützige GmbH as part of the ‘Pilot-SBG | Bioresources and hydrogen to methane as fuel’ project, is a research and demonstration platform commissioned by the Federal Ministry for Transport as part of the German government's mobility and fuel strategy. The pilot plant was officially commissioned on 18 March 2025.

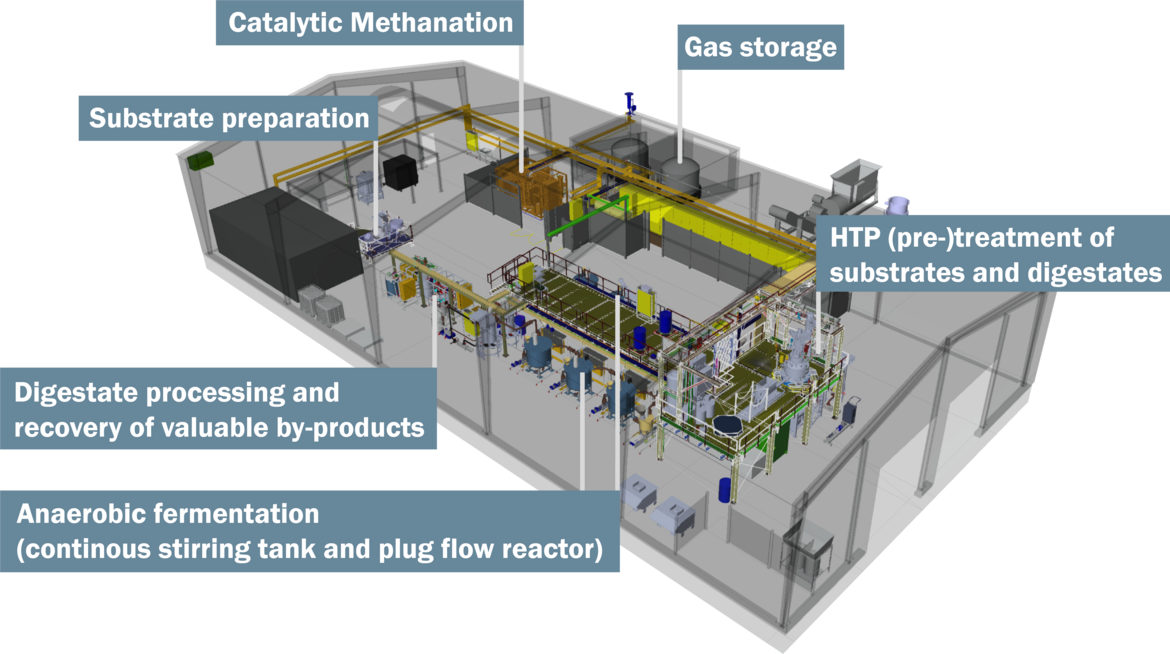

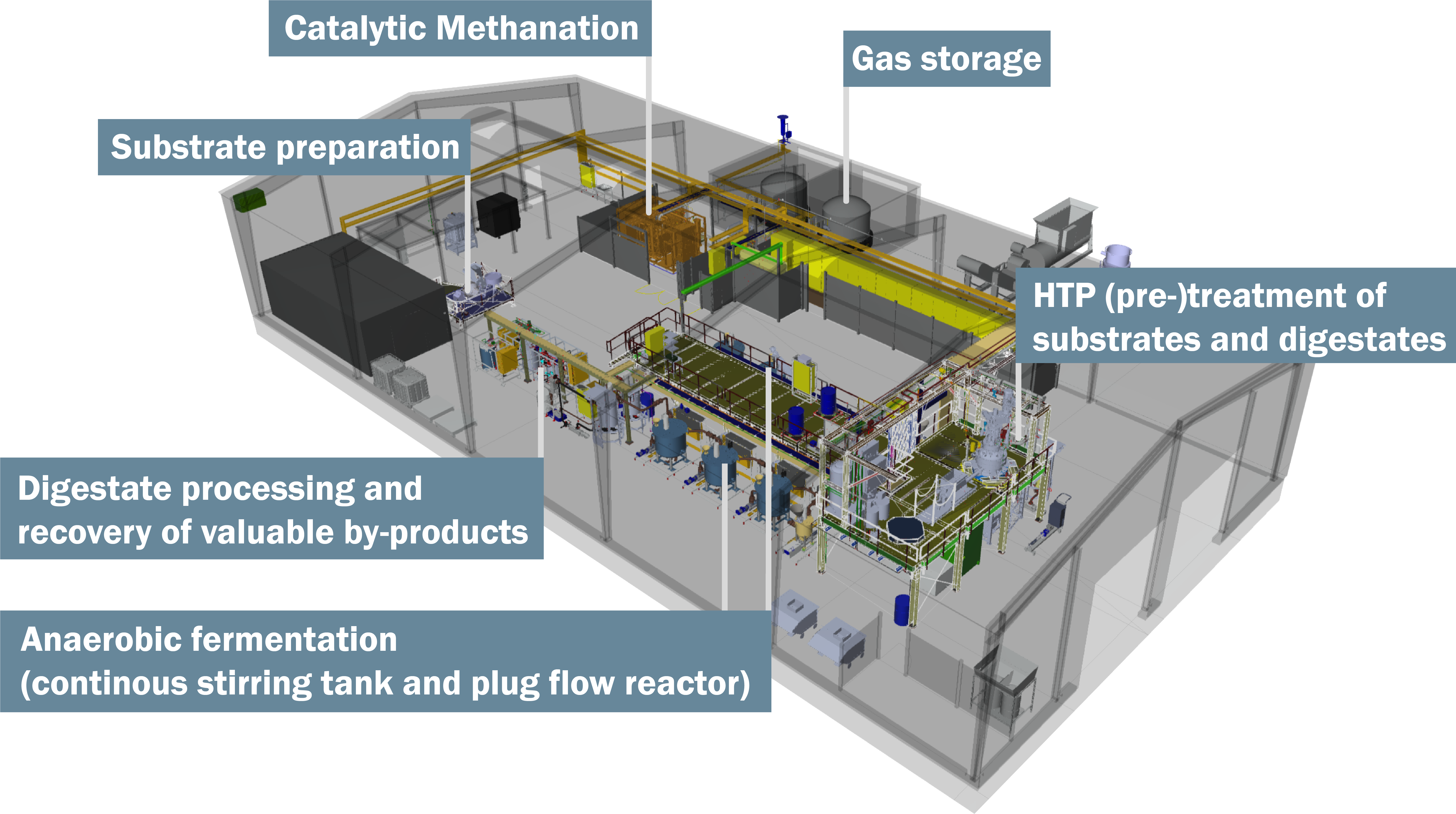

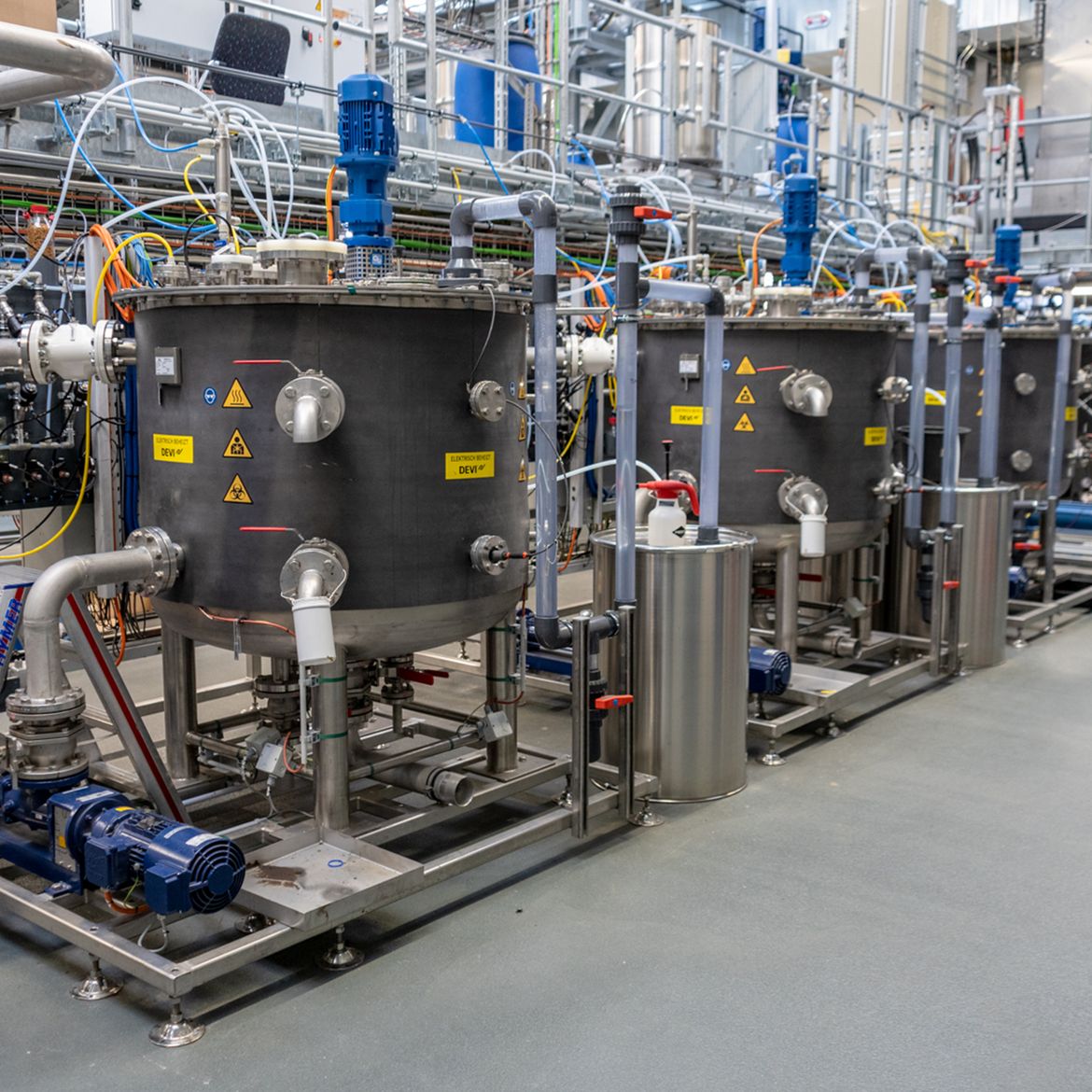

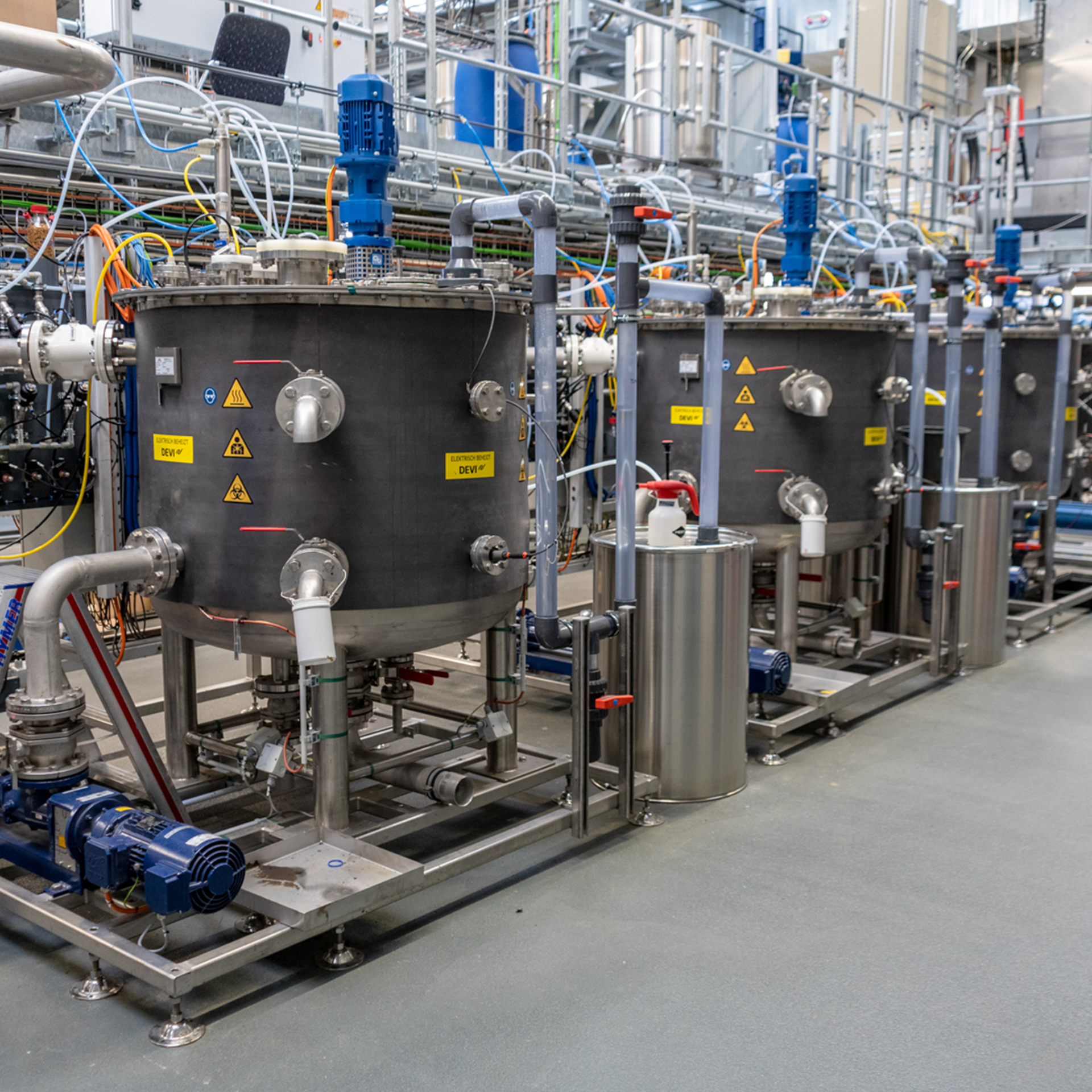

At its core, the pilot plant combines the anaerobic fermentation of selected residual and waste materials with the subsequent methanation of the resulting biogas. Innovative upstream and downstream processes increasing the resource efficiency and provide valuable by-products.

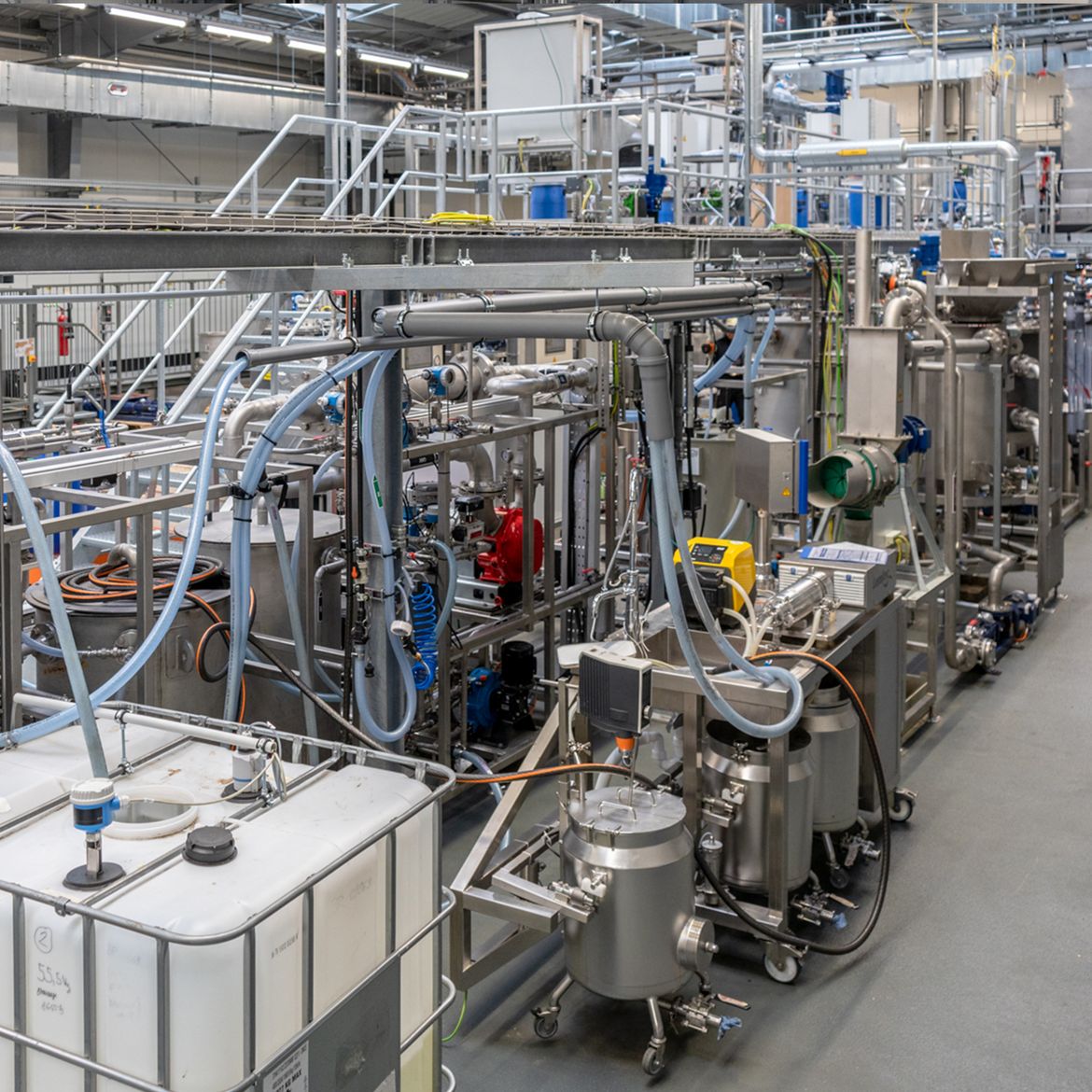

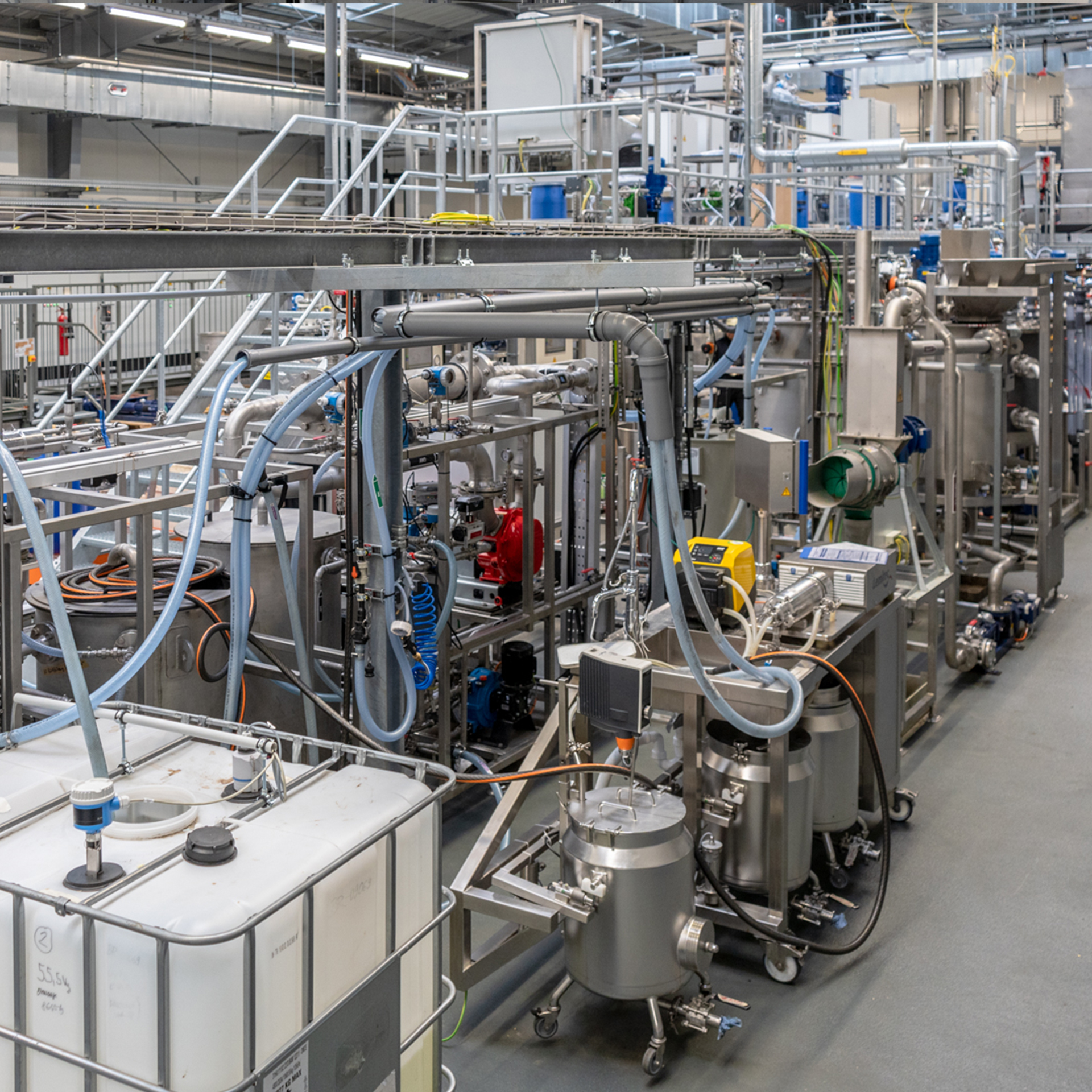

For the two campaigns, agricultural by-products in the form of straw and cattle manure as well as urban waste such as organic and green waste are sourced and processed regionally. The process chain essentially consists of the specific preparation of the raw materials, the subsequent optional pre-treatment using a hydrothermal process, the anaerobic fermentation to biogas in two parallel fermenter lines of different designs, the catalytic methanation of the CO2 in the biogas with the addition of hydrogen and the processing of the fermentation residues. Various aggregates of a separation cascade including optional hydrothermal post-treatment are available for digestate processing. As a result, renewable methane is produced as the main product at the pilot plant.

This is to be used in a subsequent tank facility in compressed form as renewable CNG in the DBFZ vehicle fleet. According to the current planning status, it can be assumed that 0.2-1.2 t of raw materials will be processed monthly in the final pilot operation and two car tank fillings of renewable CNG will be provided.

The representation of the entire process chain in one plant is unique in Germany on this scale. The pilot plant serves to gain knowledge, for example, on the interaction of components and apparatus or the influence of process parameters on its stability and yield. Its capacity has been selected to provide sufficient flexibility for research and development and to be cost-justifiable. After the operating campaigns planned from 2023, the plant will be available to actors from science and industry alike as a technology platform for research and development and is designed in such a way that different technology modules can be used flexibly. To a limited extent, it can also be used for these purposes already during the project term Pilot-SBG.

Technical overview

Modules of the pilot plant

Substrate preparation

In the substrate pretreatment module, the biomass is prepared. The primary objective is to adjust particle sizes and fiber lengths of the substrates (< 20 mm) as well as the dry matter content of the substrate mixtures such a way that the plant operation is as unobstructed as possible. Given the varying properties of the different biomasses such as cereal straw, green cuttings or biowaste - different processing steps for coarse, fine, dry and wet comminution are necessary. This module does not consist of a single plant unit, but of several aggregates that are operated in batches, as well as a central weighing station and areas for filling, transferring and mixing the substrates. The aim is to provide storable and conveyable batches for the subsequent process steps.

Anaerobic fermentation

During fermentation, the processed biomasses are broken down by microorganisms in a controlled process, under the absence of oxygen and at a suitable process temperature. The organic matter contained produces biogas, a mixture of mainly methane and carbon dioxide. For this purpose, two separate reactor lines are available for agricultural (cereal straw and cattle manure) and urban (green waste and biowaste) bioresources, which differ in their mode of operation and the possible dry substance contents of the resources. Thus, this constellation allows a direct comparison of the reactor systems, the biogas qualities and quantities of each digester, the influence of hydrothermal pretreatment of the substrates and thus the methane yield over each process stage. Considering economic and ecological aspects, the results serve as a planning basis for process scaling and ideal operating points. A compromise between substrate utilization and costs has to be found.

Catalytic methanation and gas purification

The biogas mixture of the two digester lines is taken from a gas buffer, cleaned and upgraded to methane (CH4), the so-called methanation. In the first step, the biogas is cleaned without pressure and at ambient temperature by using adsorbents, such as activated carbons or metal oxides, to separate catalyst- and plant-damaging components, especially hydrogen sulfide (H2S) and other sulfur-containing molecules, from the gas. The gas is then compressed to 20 bar, heated to 150 °C and passed through a police filter so that the last traces of H2S are separated. In the second step, biogas upgrading in the methanation reactor, hydrogen (H2) is added to the biogas, which reacts with the carbon dioxide (CO2) to form methane. The amount of H2 is adjusted to the CO2 content in the gas. Downstream of the reactor, the gas is depressurized and cooled to ambient temperature to condense and separate the water formed during the reaction. Subsequently, excess CO2 is removed from the dry gas in a two-stage NaOH scrubber. The target for the purified product gas is to meet DIN EN 16723-2 for use as a transport fuel.

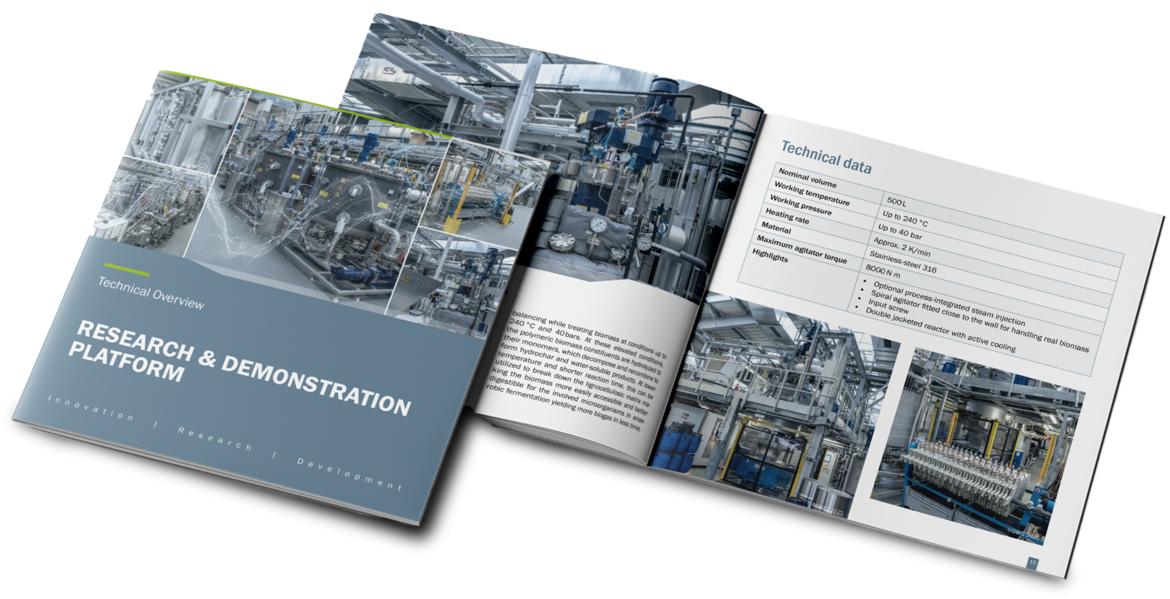

Hydrothermal preparation and treatment

As part of the pilot plant for renewable methane, the introduction of hydrothermal processes is used for pre- and post-treatment of the bioresources. In this process, the aqueous biomasses are treated at up to 240 °C and 40 bars. In the course of the reaction, the polymeric biomass components are first broken down into their monomeric building blocks by hydrolysis, and then a broad spectrum of products ranging from fine chemicals to so-called hydrochar are generated by decomposition and recombination. In the context of pretreatment, a stainless-steel reactor with heating jacket, agitator and steam generator is used primarily for pre-digestion, i.e. hydrolysis of the biomasses, in order to achieve a higher methane yield with a low retention time in fermentation process. The post-treatment of the digestate aims for further material value creation. Various digestate from pilot plant campaigns will be hydrothermally carbonized and the suitability of the hydrochar produced for 1) gasification and 2) carbon capture and storage (CCS) via soil application will be investigated. The goal of gasification is to provide a syngas for the chemical industry, thereby providing renewable carbon with the goal of sequestration for material use.

Digestate treatment

In the digestate treatment module, the portion of biomass that has not been fermented into biogas is treated to produce dischargeable water, a solid organic farm fertilizer rich in nitrogen and phosphorus, and a liquid inorganic farm fertilizer rich in nitrogen and potassium. In addition, a recirculate can be provided from the liquid phase of the digestate for mixing in the biogas process. The first step of digestate treatment consists of separating the solid phase from the liquid phase by means of a press screw separator and decanter centrifuge or chamber filter press with the addition of flocculants. For further treatment or concentration of the liquid phase, the membrane technologies ultrafiltration and reverse osmosis are available. With the separation cascade, an average of 0.1 - 0.5 m³ of digestate can be processed per day with the aim of achieving a volume reduction of at least 50%. The quantity and quality of the recovered nutrients or farm manure depends on the biomass used and the process conditions in the anaerobic fermentation. During processing, all relevant process parameters are recorded for monitoring the separation processes and for determining mass and energy balances.

![[Translate to Englisch:] Baustart Band Pilotanlage DBFZ](/fileadmin/_processed_/2/8/csm_Cut_Pilot_SBG_1_10b60e29ae.jpg)

![[Translate to Englisch:] Baustart Band Pilotanlage mit admin. Geschäftsführung und Projektleitung Pilot-SBG](/fileadmin/_processed_/b/4/csm_Cut_Pilot_SBG_2_f6b28ab0e0.jpg)

![[Translate to Englisch:] Projektteam Pilot-SBG Baustart DBFZ Leipzig Pilotanlage für erneuerbares Methan](/fileadmin/_processed_/8/1/csm_Team_Pilot_SBG_791b72c528.jpg)