Available unused substrate potentials and obstacles to their energetic use in German biogas plants - Survey of livestock farmers without biogas plant

In Germany, considerable potential for agricultural by-products currently remains untapped. In particular, large quantities of manure (liquid and solid), which could be used to generate energy in biogas plants, are still available. A survey of livestock farmers, who do not operate their own biogas plants, was conducted to determine the reasons why the available substrates remain unused for energy generation.

The survey intended to provide information on available manure quantities, existing manure removal techniques and manure storage, as well as information on key reasons why manure is not used for biogas production. In addition, it will be recorded which changes are necessary from the point of view of the livestock farmers in order to promote the energetic use of liquid manure.

In the following, results for the distribution of the response and evaluations of the relevant questions are presented.

Dispatch and return

The survey was conducted in summer 2019 as an online survey using a partially standardized questionnaire. The survey was advertised to farmers via online editions of various agricultural magazines (Elite, TopAgrar, BauernZeitung) and DBFZ newsletters and they were invited to participate. Participation in the survey was via an online questionnaire. It was also possible to download and complete the questionnaire as a form.

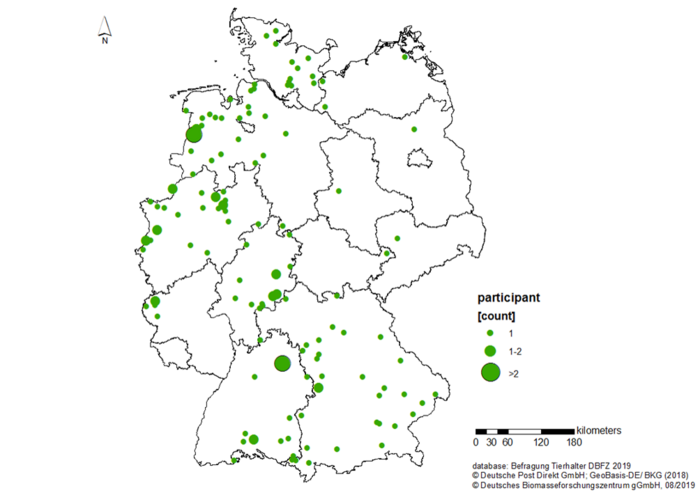

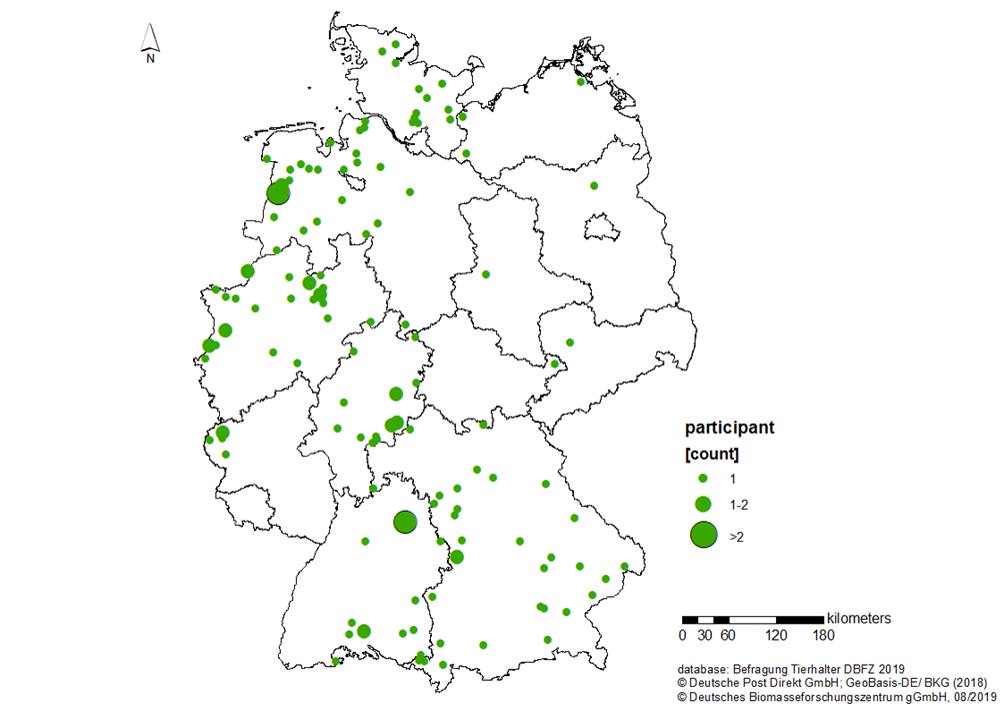

In total 147 responses from livestock farmers are available for evaluation. Figure 1 and Table 1 show the regional distribution of the responses. It turns out that the return flow is unevenly distributed. In eastern Germany, the number of participants is very small. In total, only 7 responses were received for the federal states of Mecklenburg-Western Pomerania, Brandenburg, Saxony-Anhalt, Saxony and Thuringia. More than half of the total number of participants in the survey can be attributed to livestock farms in Bavaria, Lower Saxony and North Rhine-Westphalia. With regard to the regional distribution of agricultural holdings with cattle, the distribution of the return flow is well in line with the total stock. Federal states with comparatively many cattle farms also show the largest share in the return flow (see Table 1) (Destatis 2019).

| response [number] | share response [%] | distribution of agricultural holdings with cattle [%] |

Baden-Wuerttemberg | 14 | 9,5 | 11,2 |

Bavaria | 32 | 21,8 | 31,8 |

Berlin/ Bremen/ Hamburg | - | - | 0,2 |

Brandenburg | 1 | 0,7 | 3,0 |

Hesse | 15 | 10,2 | 5,8 |

Mecklenburg-Western Pomerania | 3 | 2,0 | 2,3 |

Lower Saxony | 28 | 19,0 | 14,7 |

Northrhine-Westphalia | 26 | 17,7 | 12,0 |

Rhineland-Platinate | 6 | 4,1 | 3,5 |

Saarland | - |

| - |

Saxony | 1 | 0,7 | 0,5 |

Saxony-Anhalt | 1 | 0,7 | 4,8 |

Schleswig-Holstein | 12 | 8,2 | 2,1 |

Thuringia | 1 | 0,7 | 5,3 |

anonymous | 7 | 4,8 | 2,9 |

total | 147 | 100 | 100 |

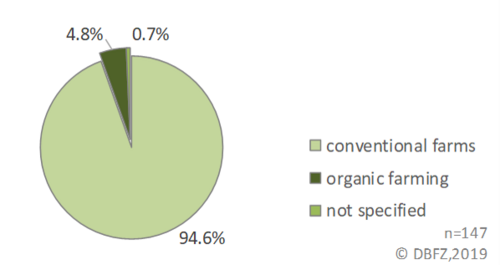

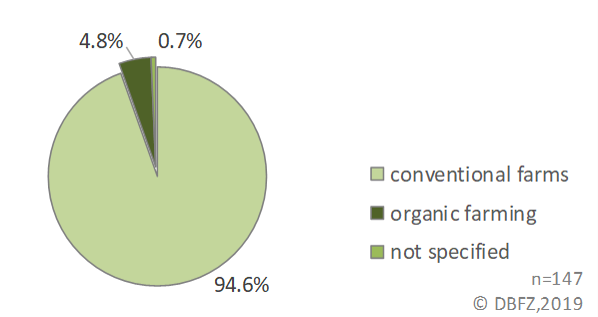

The majority of the participants in the survey stated that they operate the livestock holding as a full-time occupation. About 11 % of the participating livestock farmers state that animal husbandry is a sideline activity. With regard to the type of farm, feedback mainly came from conventional farms (about 95 %). About 5 % of the participants indicated that they run an organic farm (see Figure 2).

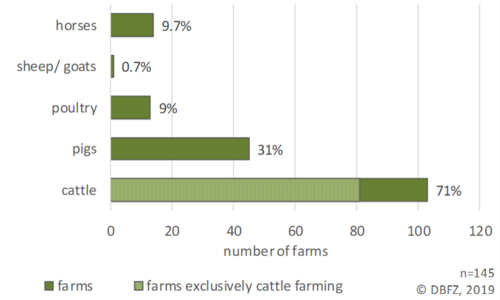

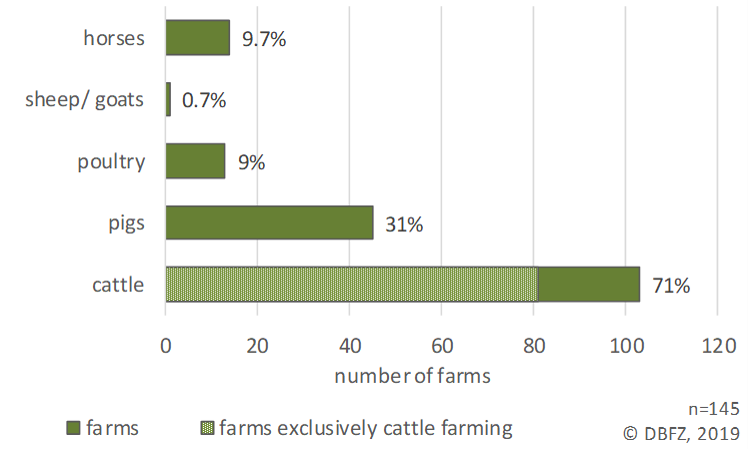

With regard to the business orientation of the survey participants, farms with cattle farming dominate (exclusively or in addition to other livestock farming). They were addressed via the corresponding online journals due to the focus of the project. 71 % of the participants say that they keep cattle (lat. bovis) (see Figure 3). 56 % of the livestock farmers of the survey solely have cattle in their herds (n=81). In addition, about 31 % of the farms report that they raise pigs, 12 of them exclusively. Farms raising poultry, horses, sheep or goats account for only a small proportion of the returns.

A breakdown of the available quantities of manure from livestock farms shows that the average available quantities of liquid and solid manure from cattle and pigs exceed 4,500 t/a (corresponds to approx. 15 - 26 kW install. el. output, depending on the substrate). About 1/4 of the participants state that the available quantities of cattle manure (liquid/ solid) are over 6,500 t/a (corresponds to about 50-60 kW install. el. output) (see Table 2).

Amount manure (solid/liquid) | Mean value [t(a] | Median [t/a] | 1st quartile [t/a] | 3rd quartile [t/a] | Number n |

cattle | 4.740 | 3.500 | 1.500 | 6.500 | 86 |

pig | 4.931 | 2.450 | 1.800 | 4.625 | 42 |

poultry | 665 | 555 | 500 | 800 | 10 |

horse | 312 | 100 | 12,5 | 500 | 13 |

Results

Manure removal technology

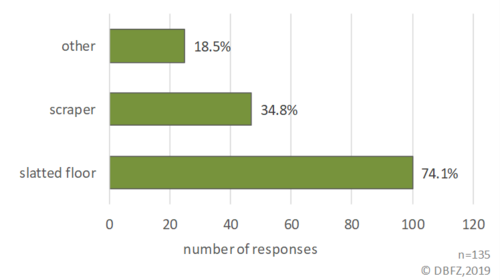

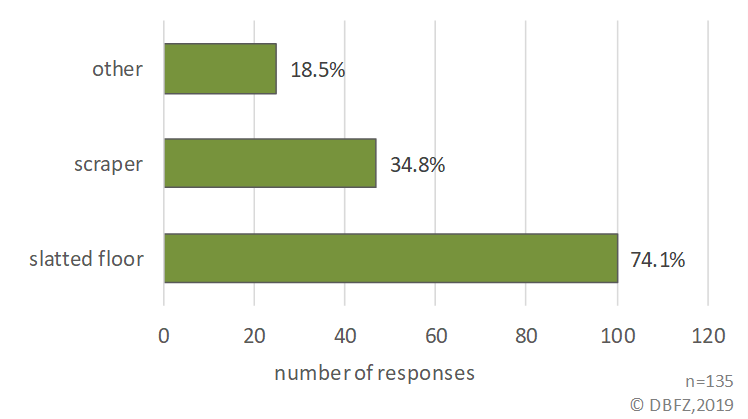

The primary manure removal technology used on the farms is slatted flooring (see Figure 4). Around 74 % of the livestock farmers indicated in the survey that they had slatted floors as the predominant manure removal technique. Approximately 35 % of respondents stated that they use scrapers (exclusively or in combination with other manure removal techniques) in their operation. The term "other" refers primarily to deep litter and pedal dung. In addition, other manure removal systems such as manure belts, wheeled loaders, manual manure removal and compost stables only play a minor role. Livestock farms that currently supply part of the available amount of manure to external biogas plants, mainly also have slatted floors. In fact, about 72 % of these farms use slatted floors. As shown in Figure 4, there are hardly any differences in the manure removal techniques used by the farms considered.

Manure storage

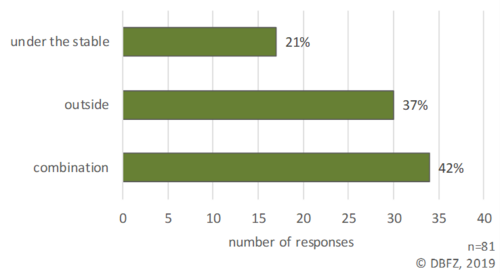

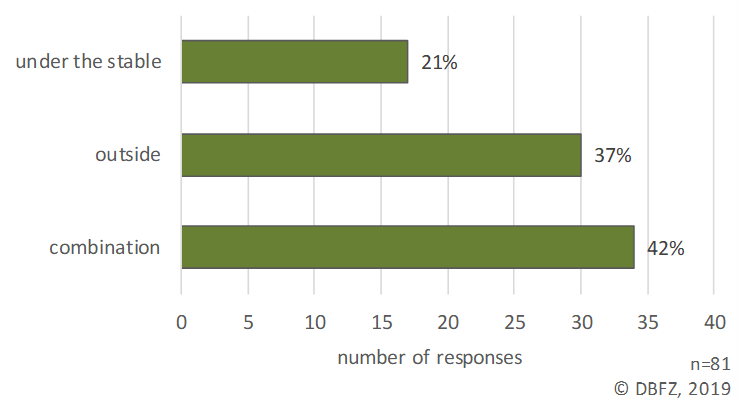

The majority of manure on cattle farms is stored in a combination of indoor storage and outdoor storage. Around 42% of the participants stated this for their storage of liquid manure. Around 21% of farms store liquid manure under the barn alone (see Figure 5). Only those holdings, which exclusively keep cattle, are taken into account here.

The information on bedding in livestock farming shows that straw is the main type of bedding used. About 87% of the participants stated that they use straw as bedding. In addition, lime and sawdust play an important role. These are used by around 16 % of the farms and are often used in addition to straw. Table 3 shows the results of the survey. The term "other" includes additional bedding materials such as compost soil and coffee powder.

Bedding | Mentions [Number] | Share of participants (n=79) [%] |

straw | 69 | 87,3 |

lime | 13 | 16,5 |

dung | 5 | 6,3 |

sawdust | 12 | 15,2 |

other | 2 | 2,5 |

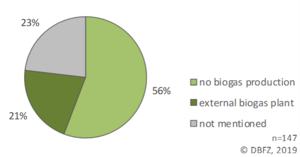

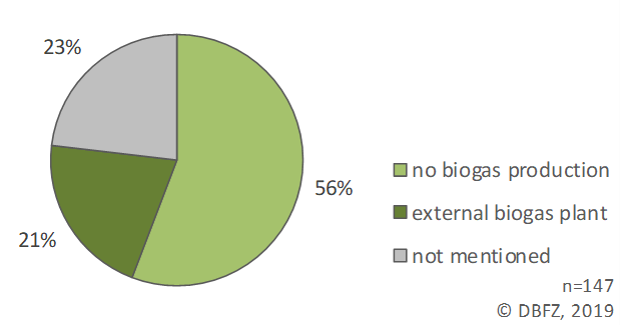

Potential biogas utilization

In the context of the survey, 31 livestock farmers without an own biogas plant stated that the available quantities of liquid and solid manure are currently already being supplied, either proportionately or completely, to an external biogas plant. This corresponds to about 21% of the respondents. The majority of respondents stated that liquid and solid manure are currently not used for biogas production (see Figure 6).

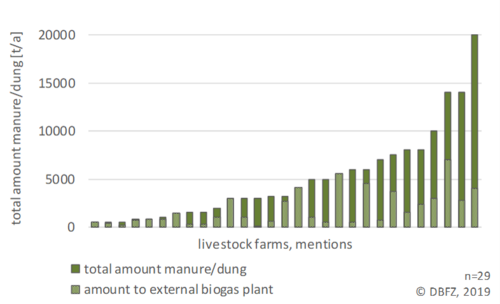

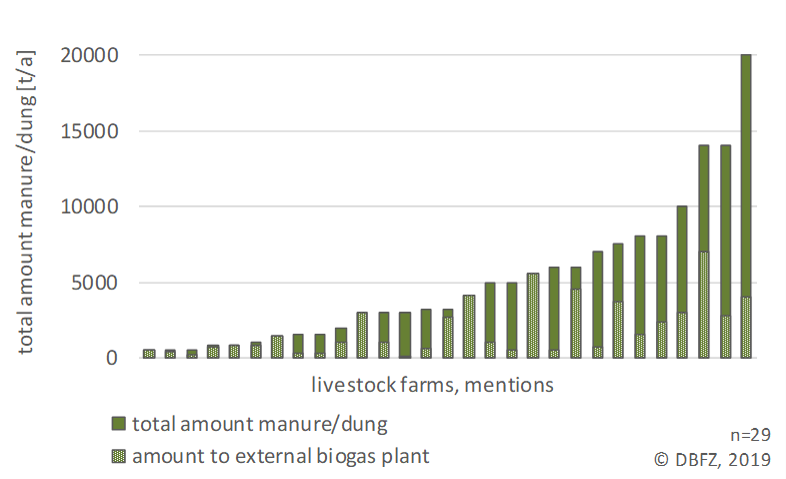

Figure 7 shows the quantities of manure (liquid and solid) used for biogas production. Information is available for 29 livestock farmers on the total amount of manure available and the proportion delivered to an external biogas plant. On average, around 50 % of the total quantities at the site are passed on to biogas plants. Half of the respondents stated that more than 35 % of the total amount of manure is delivered to an external biogas plant.

Table 4 shows the average proportion of the available total quantity of manure (liquid and solid) used in an external biogas plant. It can be seen that with an increasing total quantity of liquid and solid manure at the location of the cattle farm, the proportion of manure that is delivered to external biogas plants decreases. Livestock farmers who produce comparatively small quantities of liquid and solid manure at their farm site (≤ 1,000 t/a) on average transfer around 80 % of the available quantities to a biogas plant. On the other hand, livestock farmers with high manure quantities at the farm site give significantly fewer substrates of the total quantity available for biogas production to a biogas plant (in average 30 %). It should be noted that, due to the small number of cases, this only represents a trend, but not statistically reliable results. More extensive surveys are needed for further consideration and validation of the results.

Total amount liquid/solid manure [t/a] | Medium share delivered to biogas plant [%] | Number n |

≤ 1.000 | 80 | 6 |

1.001 – 5.000 | 47,1 | 12 |

5.001 – 10.000 | 40,4 | 8 |

> 10.000 | 30 | 3 |

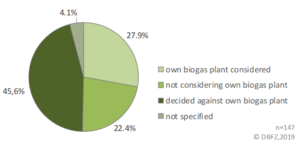

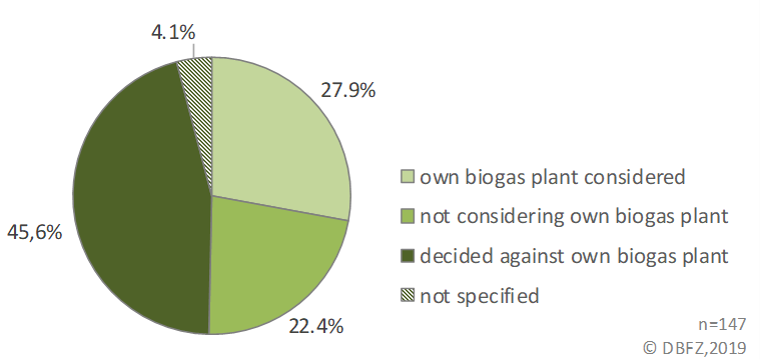

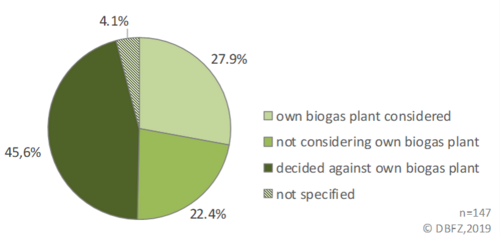

With regard to the energetic utilization of the available quantities of manure and dung in biogas plants, the livestock farmers were asked whether the construction of an own biogas plant had previously been considered. Around 73 % of the respondents indicated that they had already considered this. However, the majority of livestock farmers decided not to build their own biogas plant (see Figure 8). About 22 % of the respondents stated that they had not yet considered setting up their own biogas plant. The majority of livestock farmers, who are currently already supplying manure to external biogas plants, have decided against a biogas plant of their own (about 55 %).

Obstacles to the utilization of biogas

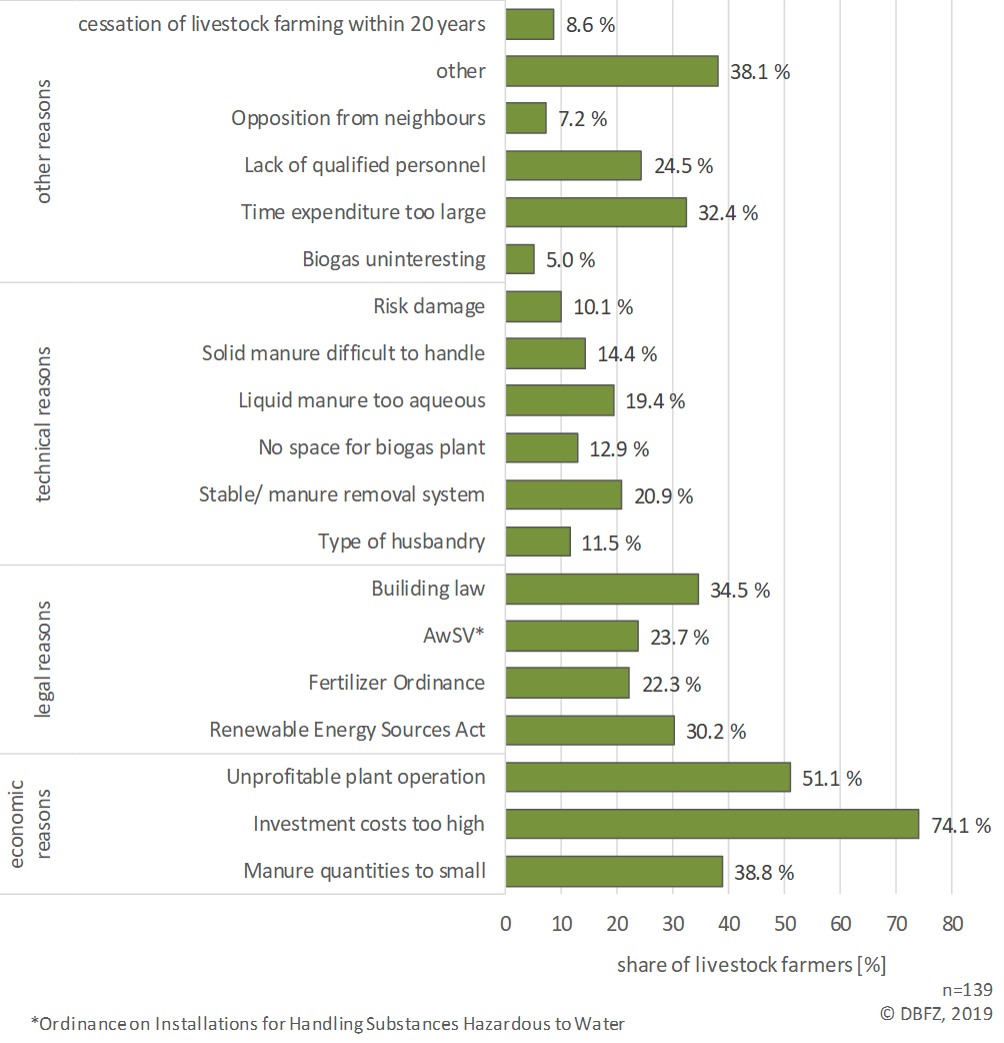

The livestock farmers state numerous different reasons why liquid and solid manure are not or not completely used for biogas utilization. Feedback on this has been received from 139 livestock farmers. The majority of livestock farmers name economic and legal aspects as major obstacles to the use of biogas. Around 96 % of the respondents stated economic reasons against the use of manure in a biogas plant. Legal aspects were also mentioned by around 94 % of livestock farmers as an obstacle to the energetic use of the substrates (see Figure 9).

An analysis of the reasons against a (complete) utilization of manure in a biogas plant can be found in Figure 10. It becomes clear that economic reasons are named by the majority. A major obstacle to the use of biogas is the high investment costs for a biogas plant. Around 74 % of the respondents indicated this as an obstacle to the use of manure for biogas production. In addition, unprofitable plant operation, building regulations, high expenditure of time and other reasons are mentioned. Technical aspects represent significantly fewer obstacles to a biogas use.

A closer look at the reasons against a biogas plant among livestock farmers who claimed to have decided against owning their own biogas plant shows a very similar distribution. Contrary to the distribution of the barriers shown in Figure 10, the energy content of the slurry (slurry too aqueous), other reasons and the unprofitable operation of a biogas plant are named as barriers much more frequently by those livestock farmers who deliberately decided against a biogas plant. Table 5 shows the results.

Obstacle | mentions [number] | Share of participants (n=67) [%] | |

Economic reasons | Manure quantities to small | 20 | 29.9 |

Investment costs too high | 45 | 67.2 | |

Unprofitable plant operation | 38 | 56.7 | |

Legal reasons | Renewable Energy Sources Act | 21 | 31.3 |

Fertilizer Ordinance | 17 | 25.4 | |

AwSV* | 14 | 20.9 | |

Building Law | 24 | 35.8 | |

Technical reasons | Type of husbandry | 4 | 6.0 |

Stable/ manure removal system | 15 | 22.4 | |

No space for biogas plant | 6 | 9.0 | |

Liquid manure too aqueous | 20 | 29.9 | |

Solid manure difficult to handle | 12 | 17.9 | |

Risk damage | 6 | 9.0 | |

Other reasons | Biogas uninteresting | 1 | 1.5 |

Time expenditure too large | 23 | 34.3 | |

Lack of qualified personnel | 19 | 28.4 | |

Opposition from neighbours | 3 | 4.5 | |

other | 34 | 50.7 | |

Cessation of livestock farming | 4 | 6.0 | |

* Ordinance on Installations for Handling Substances Hazardous to Water | |||

Adjustments to increase the energetic use of liquid and solid manure

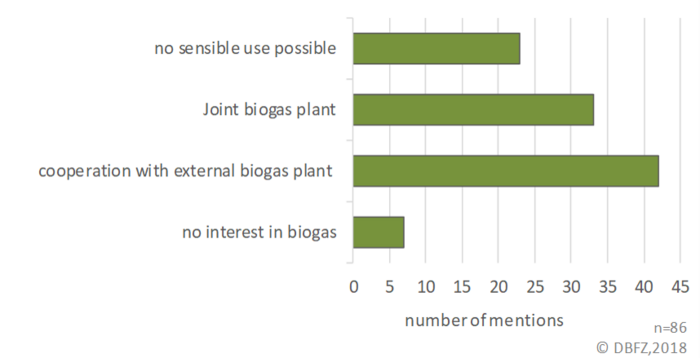

Within the scope of the survey, it was determined which adjustments/changes would be necessary from the perspective of the livestock farmers in order to achieve a complete energetic use of liquid and solid manure. About 1/3 of the respondents stated that none of the changes could result in a decision for an own biogas plant because there was either no interest in biogas or a sensible use of manure was not seen possible (see Figure 11). Nearly half of the respondents stated that the use of the available substrates in an external biogas plant via cooperation is conceivable. A joint biogas plant would also be an option for about 1/3 of the livestock farmers.

According to the respondents, an operation of their own biogas plant (new construction) can only be considered if different economic aspects change. Accordingly, the construction and operation of a biogas plant can only be regarded if:

- the investment costs for biogas plants decrease

- profitable electricity utilization is possible and

- there is a lower financial risk during the construction and operation of the biogas plant.

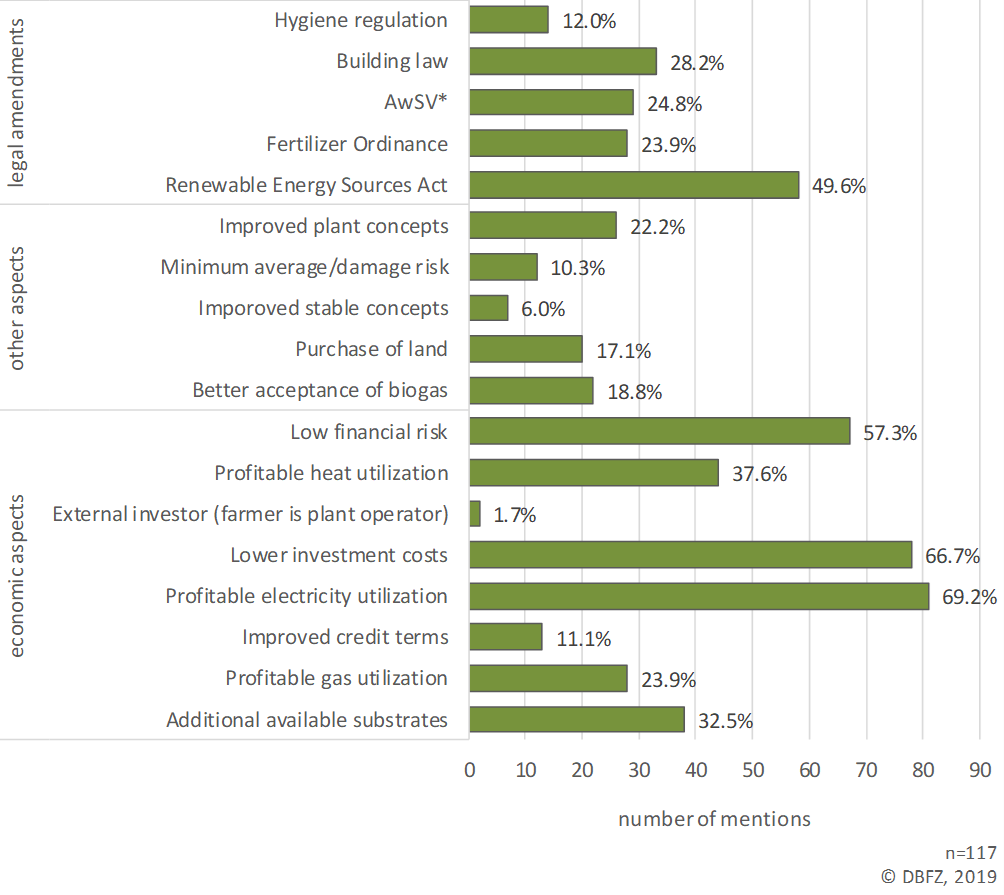

Figure 12 shows the measures and improvements required to achieve complete energy use of liquid and solid manure. In addition to economic aspects, the amendments to the Renewable Energy Sources Act (EEG), which has primarily promoted the construction and operation of biogas plants in recent years, are mentioned above all.

Summary

This survey of livestock farms without their own biogas plant shows that livestock farmers often consider biogas production as an energetic use of liquid and solid manure. The vast majority of these livestock farmers have already considered the subject of "their own biogas plant", but in the end about 2/3 of the respondents decided against having their own BGA or did not consider it from the outset. Economic and legal reasons are cited as the main obstacles to an own biogas plant (> 90 % of farmers). High investment costs, unprofitable plant operation and insufficient quantities of manure are the main obstacles identified. With regard to necessary legal adjustments and changed framework conditions, about 50 % of the survey participants stated that the use of the available substrates in an external biogas plant is conceivable through cooperation. Similarly, for about 1/3 of the livestock farmers, a joint biogas plant would be an option in order to feed the available quantities of slurry and manure into energy recovery. From the point of view of livestock farmers, lower investment costs, profitable plant operation and adjustments to the Renewable Energy Sources Act (EEG) are the key aspects that need to be adapted to biogas production.

Acknowledgements

The research project ChinaRes (funding code 22025816) was funded by the Federal Ministry of Food and Agriculture based on a decision of the Parliament of the Federal Republic of Germany. The responsibility for the content of this publications lies with the authors.

https://www.dbfz.de/en/projects/china-res/project/

16.12.2019

Statistisches Bundesamt (destatis) (2019): Land und Forstwirtschaft, Fischerei. Viehbestand. 3. Mai 2019 (Fachserie 3, Reihe 4.1). Wiesbaden. 2019.