Available unused substrate potentials and obstacles for their energetic use in Germany

Barriers to the use of liquid manure in biogas plants

Operator survey of the DBFZ

With regard to the recording of identification to the energetic use of liquid manure and residual materials, biogas plant operators were questioned as part of the annual operator survey. In addition to the existing substrate input, the aim was to record substrates that are currently unused for biogas production and to present obstacles for the energetic use of these substrates. With regard to the presentation of best-case plants, which is planned as part of the project work, the plant operators were also asked to evaluate their biogas plant with respect to liquid manure management and processes for emission reduction.

In the following, the dispatch and distribution of the return flow as well as the results of the relevant parameters are presented.

Dispatch and returns

The survey was conducted in spring 2019 as a written survey using a partially standardized questionnaire. The questionnaire was sent to around 6,900 operators of biogas plants. The reference year for data collection is 2018.

A total of 484 feedbacks from plant operators are available for evaluation. This corresponds to a response rate of 7 %. In relation to the federal state level, the response rate is mostly above 6 %. The response rates for Brandenburg, Rhineland-Palatinate and Saxony-Anhalt are comparatively low. The regional distribution of the biogas plant locations available for evaluation is shown in Figure 1.

Table 1 shows the response to the survey by size class in relation to the installed capacity of the biogas production plant. It becomes clear that systems in the medium to large output range > 500 kWel installed system output dominate the return flow.

| Installed capacity | returns [number] | share [%] |

|---|---|---|

| ≤ 75 kWel | 68 | 14,0 |

| 76-150 kWel | 24 | 5,0 |

| 151-300 kWel | 63 | 13,0 |

| 301-500 kWel | 87 | 18,0 |

| 501-1.000 kWel | 123 | 25,4 |

| > 1.000 kWel | 108 | 22,3 |

| no specification | 11 | 2,3 |

Results operator survey

Substrate input in agricultural biogas plants

Agricultural biogas plants dominate biogas production in Germany. Around 95 % of biogas plants with on-site conversion to electricity are agricultural plants in which excrements and residues from animal husbandry (all types of manure), and energy crops are used to produce biogas.

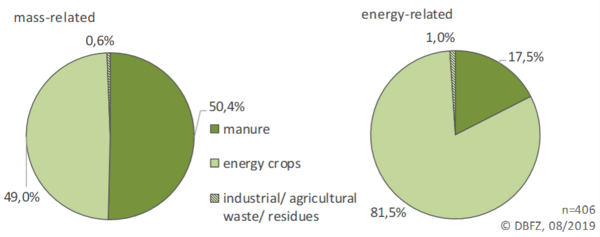

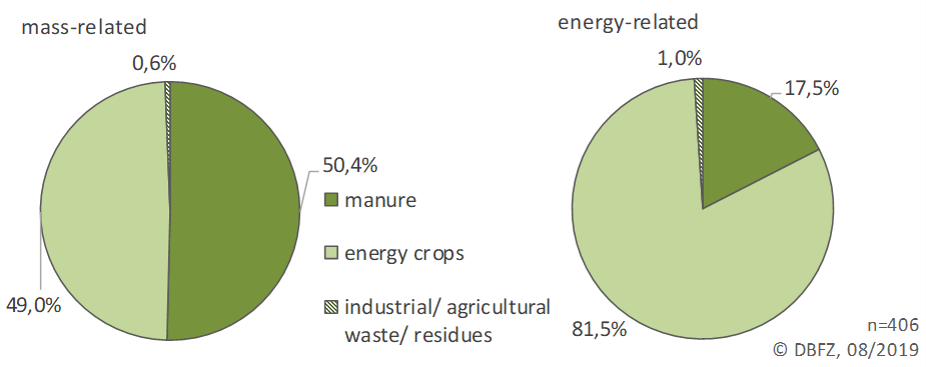

Figure 2 shows the distribution of substrates used in agricultural biogas plants. In relation to the quantities used, the proportion of animal excrement is around 50 % of the substrate input. Energy crops account for around 49 % of the substrate quantities used. In addition, small quantities of organic residues are used for biogas production. Referring to the substrates’ energy content, the distribution of the total input shifts to energy crops. Thus, about 82 % of the energy supply from agricultural biogas plants refer to energy crops.

Available substrates

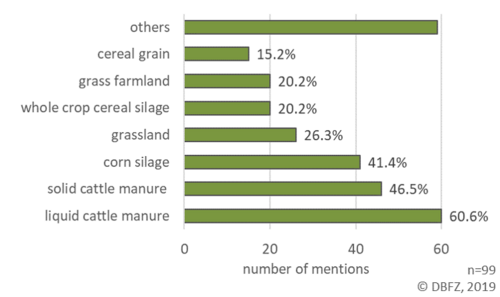

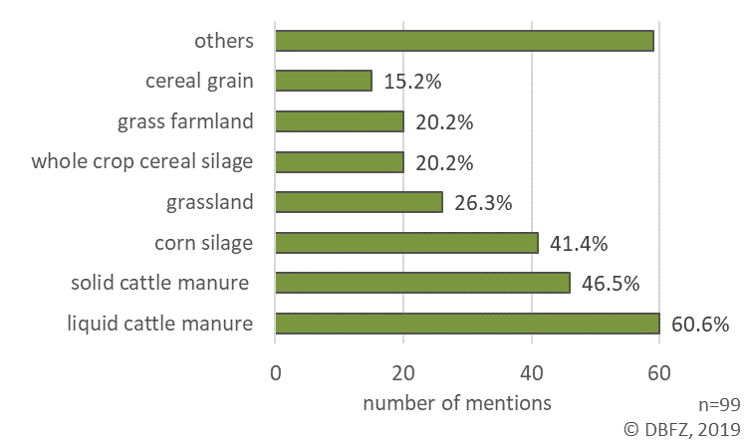

Within the scope of the operator survey, it was determined whether further substrates, which are currently not used for biogas production, are available at the plant location with a radius of about 5 km. There are 99 answers for the evaluation. On average, the operators identified 3 types of substrates that are available but not used for biogas.

Figure 3 shows the available substrates listed in the survey. About 61% of the operators stated that liquid cattle manure is additionally available for biogas production at the site (incl. a radius of 5 km). In addition, solid cattle manure and corn were named as available substrates.

In terms of the quantities available, which remain unused for biogas production to date if specified by the operators - there are differences between the individual substrates. Comparatively high available potentials for cattle manure and pig manure for the individual sites are identified. According to the operators, the average available amount of cattle manure is around 5,600 tonnes per year per operator or existing biogas plant with unused resources. At around 8,650 tonnes, the average quantities available at existing biogas production sites for pig manure (slurry) are significantly higher. Overall, larger quantities are available for animal excrement (liquid and solid manure) than for energy crops.

Obstacles to the utilization of manure for biogas production

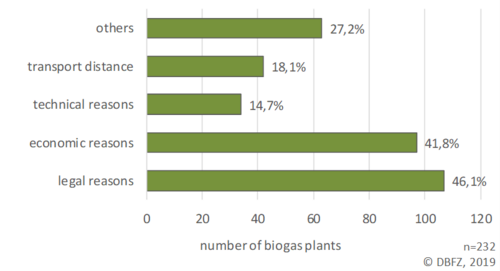

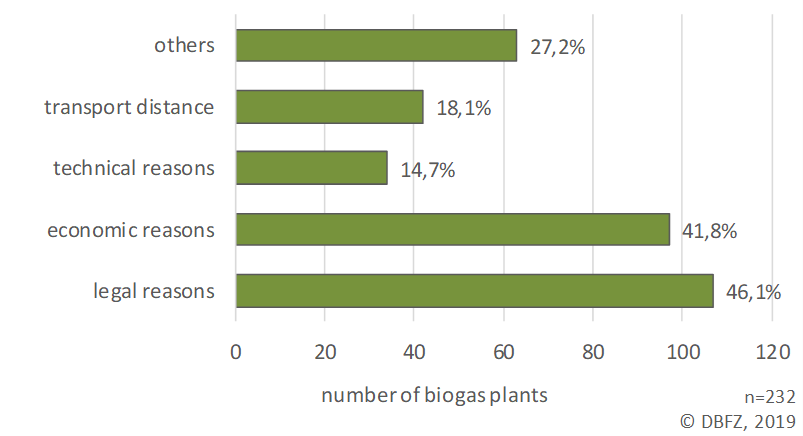

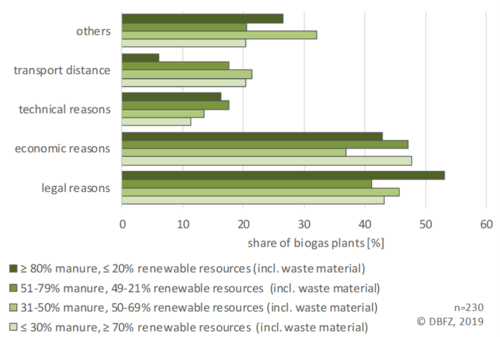

Within the scope of the survey, the reasons why available substrates still remain unused for biogas production were investigated (multiple answers possible). There are 232 responses for the evaluations. The majority of the operators gave legal and/or economic reasons. About 46% of the operators stated that legal regulations or specifications make it difficult or impossible to use their own substrates or substrates available in the vicinity for biogas production. In addition, around 42 % of the operators stated that they did not use available substrates for biogas production for economic reasons. Figure 4 shows the feedback from the survey. The category "other" mainly includes information that the own production is sufficient for the operation of the biogas plants and that there is no need to ferment additional substrates in the plant. Furthermore, the maximum rated power laid down in the Renewable Energy Sources Act (EEG), lack of acceptance, feed requirements, limited fermenter volume or poor quality of the available substrates are cited as other reasons.

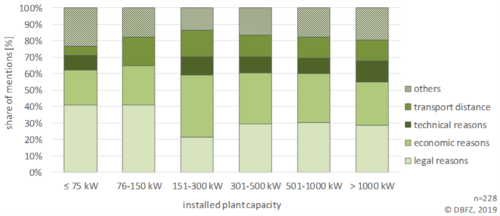

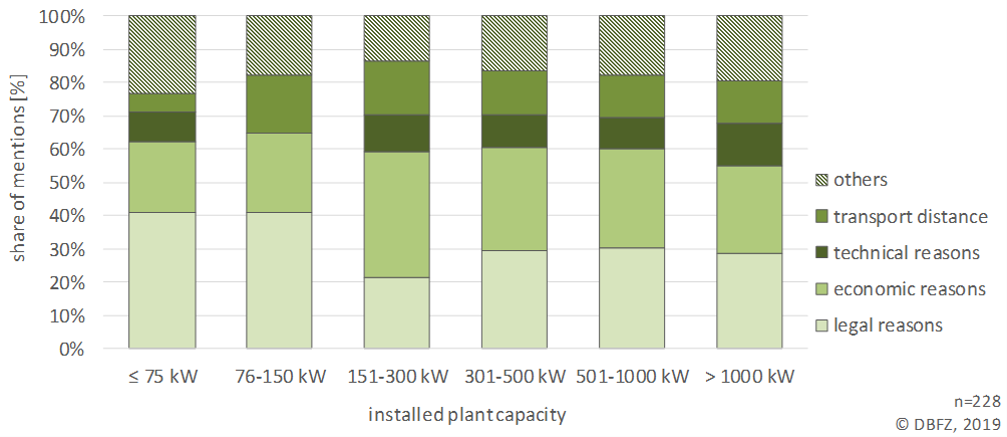

With regard to the installed capacity of the plants, it can be seen that for plants in the small capacity range (≤ 150 kWel), legal reasons are often cited as the reason that substrates remain unused (Figure 5). In the power range of 151-300 kWel, mainly economic reasons for incomplete use of the available substrates are given. In the medium to large power range, the distribution of the named obstacles is similar. In these power ranges the different reasons are rather evenly distributed.

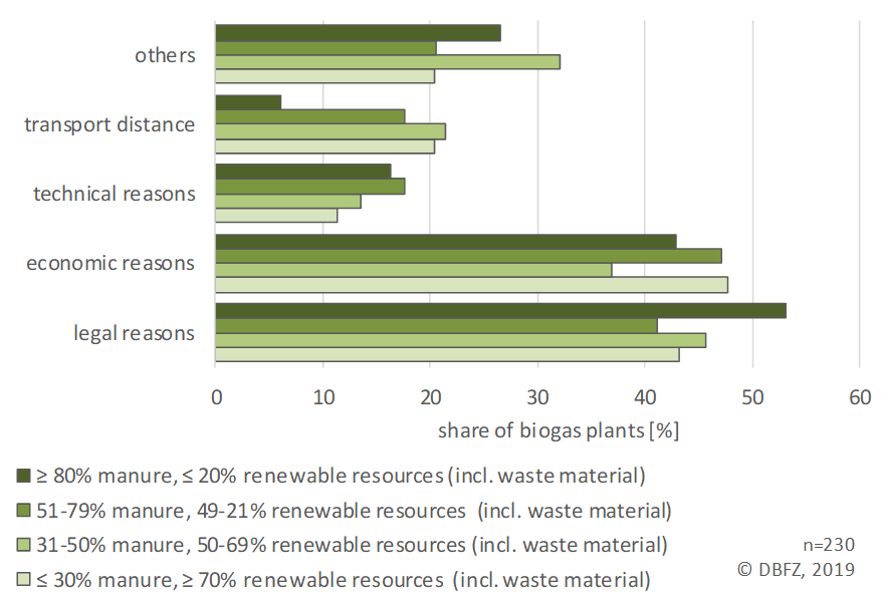

Taking into account the current substrate input in the biogas plant, the reasons for incomplete substrate use are different (see Figure 6). It becomes clear that plants with ≥ 80 % slurry/solid manure at the substrate input primarily name legal reasons as obstacles for an additional substrate input. As these plants are often small-scale manure based biogas plants according to Renewable Energy Sources Act (§27b EEG 2012, §46 EEG 2014, §44 EEG 2017), the upper limit of the installed capacity according to EEG is fixed for these plants. The installed capacity is 75 kWel for small-scale manure based biogas plants that went into operation by December 2018. In December 2018, the Energy Collection Act raised the upper limit to an installed capacity of 150 kWel (with a rated capacity of 75 kW) for small-scale liquid manure plants that subsequently went into operation. For many plant operators, these threshold values represent a major obstacle to the further use of available substrates, in particular liquid manure and solid manure. Economic reasons are cited somewhat less frequently for plants with 31-50 % slurry in the substrate input. The transport distance hardly represents an obstacle to the additional use of substrates for plants with a high use of liquid manure. This indicates that the substrates are often available directly at the site and shows also that legal requirements and economic reasons in particular hinder the use of the potential.

A differentiated analysis of the type of unused potentials and stated reasons for not using them for biogas production is hardly possible due to the very small number of cases.

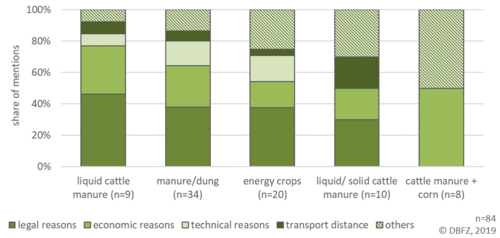

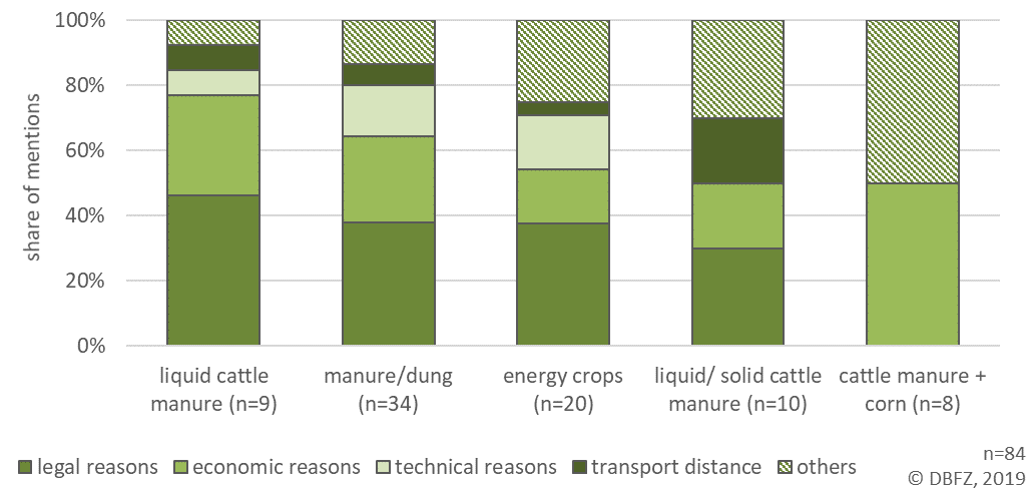

Figure 7 shows the results for selected substrate groups. Operators who have named cattle manure alone as unused potential mainly cite legal reasons as an obstacle to the energetic use of cattle manure. In addition, economic reasons are mentioned above all. Plant operators who only declare animal excrements such as slurry and manure as unused potentials, majority of them name legal reasons as an obstacle. In addition, technical and other reasons are also mentioned. Available quantities of cattle manure and solid manure together are significantly more frequently not used for fermentation in biogas plants due to the transport distance. It can be assumed that the available quantities are available in the vicinity of the plant location and that transport to the plant would not be profitable.

Manure management

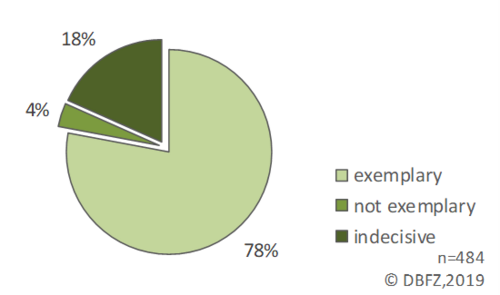

Within the scope of the project work it is intended to present best-case facilities. In this respect, the plant operators were asked to evaluate their biogas plant with regard to liquid manure management and processes for emission reduction. As a result of the survey, the operators estimate their own plant operation to be exemplary in terms of liquid manure management and emission reduction (see Figure 8). About 4 % of the operators state that the plant is not to be assessed as exemplary.

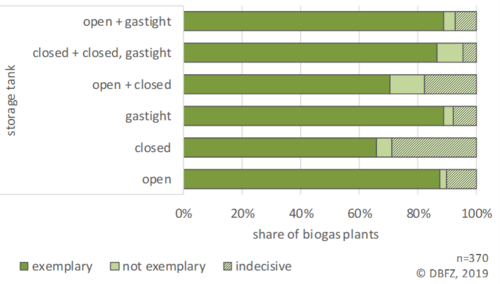

A breakdown of the assessment of the exemplary character of the plants as a function of the fermentation residue storage coverage at the plant location shows that plants with gas-tight covered residue storage facilities as well as plants with open residue storage facilities evaluate liquid manure management and emission reduction processes as exemplary. Most plant operators with closed (non-gas-tight) fermentation residue storage facilities call their liquid manure management exemplary, but significantly more operators than in other groups are also uncertain to evaluate it.

Summary

At present, animal excrement (solid and liquid manure) accounts for about 50% of the substrate input in agricultural biogas plants in Germany. Nevertheless, many substrates suitable for biogas production remain unused. In the context of the operator survey, around 60 % of operators stated that liquid cattle manure and/or solid cattle manure available at the biogas production site and in the surrounding area were not completely used for biogas production. In particular, comparatively high average potentials (> 5,500 t/year on average) are indicated for liquid cattle manure and pig manure (slurry) at the individual sites. The main reasons why these substrates remain unused at present are primarily legal and economic barriers. Plant operators with biogas plants in the low power range (<150kW installed electric power) and plants with a high proportion of liquid manure in the substrate input tend to name legal reasons as a major obstacle to the further use of liquid manure. An assessment of the plant operators with regard to liquid manure management and procedures for emission reduction at the biogas plant shows that the majority of the operators consider the biogas plants to be exemplary.