Biogas and animal husbandry in Germany

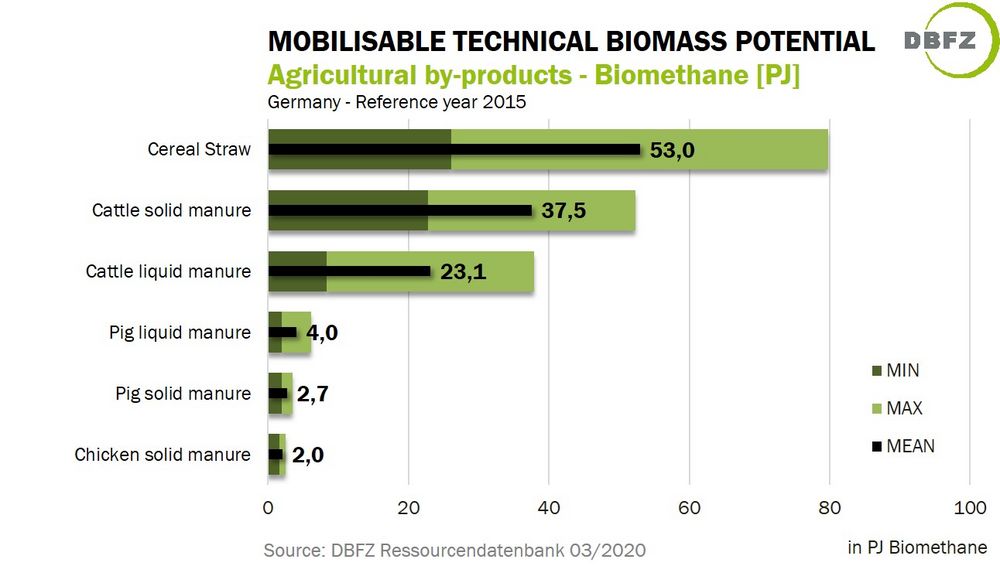

At the end of 2018, Deutsche Biomasseforschungszentrum gGmbH published a resource monitoring system for by-products, residues and waste, which is freely available at the web address http://webapp.dbfz.de. According to this, there is still considerable potential for agricultural by-products such as grain straw (on average 6.8 million tonnes DM/a), cattle manure (on average 5.6 million tonnes DM/a) and manure (on average 5.1 million tonnes DM/a) in Germany, which could be used to generate energy in biogas plants. The project "Working group Biomass residues monitoring (WG BioRestMon)" (FKZ 22019215), funded by the German Federal Ministry of Food and Agriculture (BMEL), shows that between 56 and 96 PJ/a of biomethane could be produced from cattle manure and manure alone, see figure.

The mobilisable biomass potential is the part of the technical biomass potential that can be converted into a higher-value use.

In Europe, Germany is the leader in biogas production. In Germany, biogas is mainly produced from agricultural substrates (liquid manure, energy crops) and therefore differs from other European countries. Since the Renewable Energy Sources Act (EEG) came into force in 2000, the number of biogas plants has risen steadily. The amendment of the Renewable Energy Sources Act (EEG) in 2004 and 2009 gave a clear boost to the number and installed electrical capacity of biogas plants. As a result, both the number and installed capacity of electricity generation on site and of biogas plants with gas processing technologies for biomethane production have increased significantly.

Against the background of the changes in the legal framework since 2012, the expansion of capacity in the biogas sector mainly comprises plant expansions, adjustments for flexible plant operation and a slight expansion of small liquid manure biogas plants and plants for biowaste fermentation. The former EEG supported biogas plants with a fixed feed-in tariff for 20 years, while the new form of support created in 2017 is based on tenders for electricity from renewable energies - including biomass.

For the time after the expiry of the guaranteed EEG remuneration and in view of the increasing share of fluctuating renewable energies (wind/solar) in the energy system, biogas plant operators are facing new requirements and challenges today.

The principal objective in dairy farming is the production of milk and calves for breeding or fattening.

In Germany, agricultural milk production is the most important area of animal production. In 2016, 4.3 million dairy cows produced more than 32 million tons of milk (Hans-Dieter Haenel et al., 2018; Thünen Institut, 2018; BMELV, 2010)

Germany has approximately 12.9 million heads of cattle in total, of which 4.2 million belong to the dairy cow category and 0.7 million are suckler cows. Being the country with the largest dairy herd, and also the second country with the most livestock population in the European Union, however, bovine herds continue to decline (Destatis, 2018; German Livestock e.V., 2019).

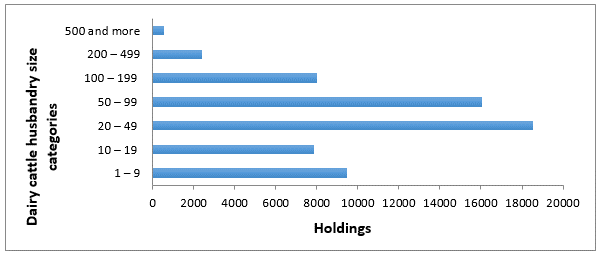

Surveys from November 2018, show that almost 12 million cattle were kept, but with a decrease of 1.2 % since May of the same year. In the case of dairy production, the number of dairy cows has fallen since the last survey (May 2018) by 1.6 % and amount to 4.1 million animals on the reporting date. The number of cattle farms counted 140,000 and was thus slightly lower (-0.7%); the number of dairy cattle farms fell by 1.8% to around 62,800. See figure 1 and 2 for more detailed information (Destatis, 2018).

Housing systems

Dairy cows are kept in barns, mainly in cubicles (Jungbluth et al., 2017). In tempered climate zones, barns provide a warm and dry environment to the animals. In summer, when temperatures are warm, pasture farming can be carried out, but this may increase the economic costs due to the logistics required to move animals from pastures to milking rooms (Jungbluth et al., 2017).

Housing systems are designed according to the animal category and production purpose. Different housing systems may be used depending on the production cycle.

The cattle herd can be managed in group or individual housing (Sommer et al., 2013; Jungbluth et al., 2017) or in tie-stalls, which is a highly debated issue in Germany. There are pronouncements in favor of banning immobilization throughout the year. In Germany, animal housing has a range of high standards and legal rules that shall improve animal welfare at a high international level (Deutscher Bauernverband, 2017).

The group housing system is the most used one in dairy husbandry. The cubicle housing has estimated following measures: space 7.8 m / animal, walk area 4.6 m² / animal; walkway at least 2.5 m wide and up to 50 m long. Cubicle housing is subdivided into cubicle barn, fully slatted floor and bedding barn (KTBL, 2006)

Depending on the size, the following different types of stables are used (Table: Stable systems by size of herd in dairy cattle report in Germany.)

| Stable systems | Stock size | ||

|---|---|---|---|

| up to 59 cows | 60 - 100 cows | more than 100 cows | |

| Typical stable system | Tie-stall, straw flow system housing, cubicle barn, multi-room barn | Cubicle barn, multi-room barn, straw flow system housing | cubicle barn |

Source:(KTBL-Schrift, 2004)

Manure removal system

For manure management, it is important to notice, that it is closely linked to the type of barn and floor; it can be managed as solid or liquid. There are two principal ways to remove the manure; mechanical or hydraulic.

Overview of a dairy cattle farming in Großkreutz, Brandenburg, Germany.

- Cubicle loose system with 51 deep boxes and draining

- Areas with solid and slatted floors

- Manure removal with scrapers: 2x / hour

- Cubicle cleaning: 2x / day

- Straw and lime bedding: 1x / 14 days

Livestock production and dairy systems in particular contribute to global warming through emission of GHG (greenhouse gas emissions), especially methane (NH4), nitrous oxide (N2O) and ammonia (NH3), either directly from the animal, or indirectly from the housing facilities. The latter may affect the emissions depending on the method used to collect, store and process the residues (manure and litter) (Grossi et al., 2019). Dairy farms are responsible for large GHG emissions, most of them from enteric fermentation and manure management (AGA, 2005). Even though the most important emission of methane comes from the animal, there are also considerable emissions of CH4, NH3 and N2O from liquid manure as well as from housing systems, storage and during field application (Montes et al., 2013; Rotz, 2017).

Manure management through anaerobic digestion (AD) for biogas production is one option for reducing the carbon footprint of milk production (Rotz and Hafner, 2011). The biogas process generates renewable energy and reduces GHG emissions.

Depending on the housing and manure removal system, fertilizer is produced as solid or liquid manure. Cubicle barns with high boxes and hard rubber mats or comfort mats, as well as cubicles with low boxes with liquid manure production and scraper removal system, are suitable systems for biogas production without manure treatment. In the case of inclined floor and deep-bed stables, solid or liquid manure is produced, with removal through the use of folding slides or mobile units, that are suitable for biogas production with manure treatment (liquefaction) (Sommer, et al., 2013; Jungbluth et al., 2013).

Bibliography

- AGA, F. (2005). Pollution from industrialized livestock production. doi.org/10.1101/gad.1884710

- Bauernverband, D. (2017). Faktencheck Haltung von Milchkühen.

- BMELV. (2010). German agriculture facts and figures. Federal Ministry of Food, Agriculture and Consumer Protection, 40.

- Destatis. (2018). Viehbestand - Fachserie 3 Reihe 1 - 3. November 2018 (Land und Forstwirtschaft,Fischerei), 49(0), 1–53.

- German Livestock e.V. (2019). German Livestock Asociation. Retrieved from www.germanlivestock.de/german-cattle.html

- Grossi, G., Goglio, P., Vitali, A., & Williams, A. G. (2019). Livestock and climate change: impact of live-stock on climate and mitigation strategies, 9(1). doi.org/10.1093/af/vfy034

- Hans-Dieter Haenel, Claus Rösemann, Ulrich Dämmgen, Ulrike Döring, Sebastian Wulf, Brigitte Eurich-Menden, Annette Freibauer, Helmut Döhler, Carsten Schreiner, B. O. (2018). Calculations of gaseous and particulate emissions from German agriculture 1990 – 2016.

- Jungbluth, Thomas; Büscher, Wolfgang & Krause, M. (2017). Technik Tierhaltung (2 Auflage). Stuttgart, Germany: Eugen Ulmer KG.

- KTBL- Kuratorium für Technik und Bauwesen in der Landwirtschaft e.V. (2006). Nationale Bewertungsrahmen Tierhaltungsverfahren (KTBL-Schr). Darmstadt, Germany: KTBL.

- KTBL-Schrift. (2004). Betriebszweig Milchviehhaltung (pp. 1–17).

- Montes, F., Meinen, R., Dell, C., Rotz, A., Hristov, A. N., Oh, J., … Dijkstra, J. (2013). SPECIAL TOPICS-Mitigation of methane and nitrous oxide emissions from animal operations: II. A review of manure management mitigation options 1. J. Anim. Sci, 91, 5070–5094. doi.org/10.2527/jas2013-6584

- Rotz, C. A. (2017). Modeling greenhouse gas emissions from dairy farms. Journal of Dairy Science, 101(7), 6675–6690. doi.org/10.3168/jds.2017-13272

- Rotz, C. A., & Hafner, S. D. (2011). Whole Farm Impact of Anaerobic Digestion and Biogas Use on a New York Dairy Farm. 2011 ASABE Annual International Meeting, 7004(11), 12. doi.org/10.13031/2037768

- Sommer, S. G., Christensen, M. L., Schmidt, T., & Stoumann Jensen, L. (2013). Animal Manure Recycling: Treatment and Management (First Edit). West Sussex, United Kingdom: John Wiley & Sons Ltd.

- Thünen Institut für Betriebswirtschaft. Steckbriefe zur Tierhaltung in Deutschland: Milchkühe (2018). Retrieved from www.thuenen.de/media/ti-themenfelder/Nutztierhaltung_und_Aquakultur/Nutztierhaltung_und_Fleischproduktion/Milchviehhaltung/Steckbrief_Milchkuehe.pdf

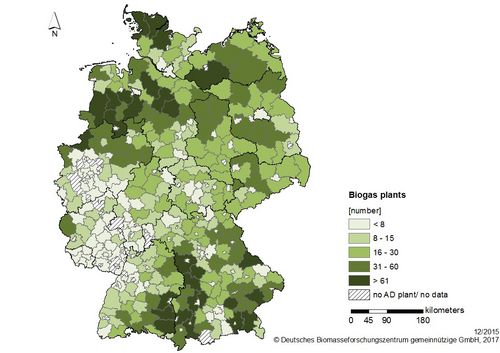

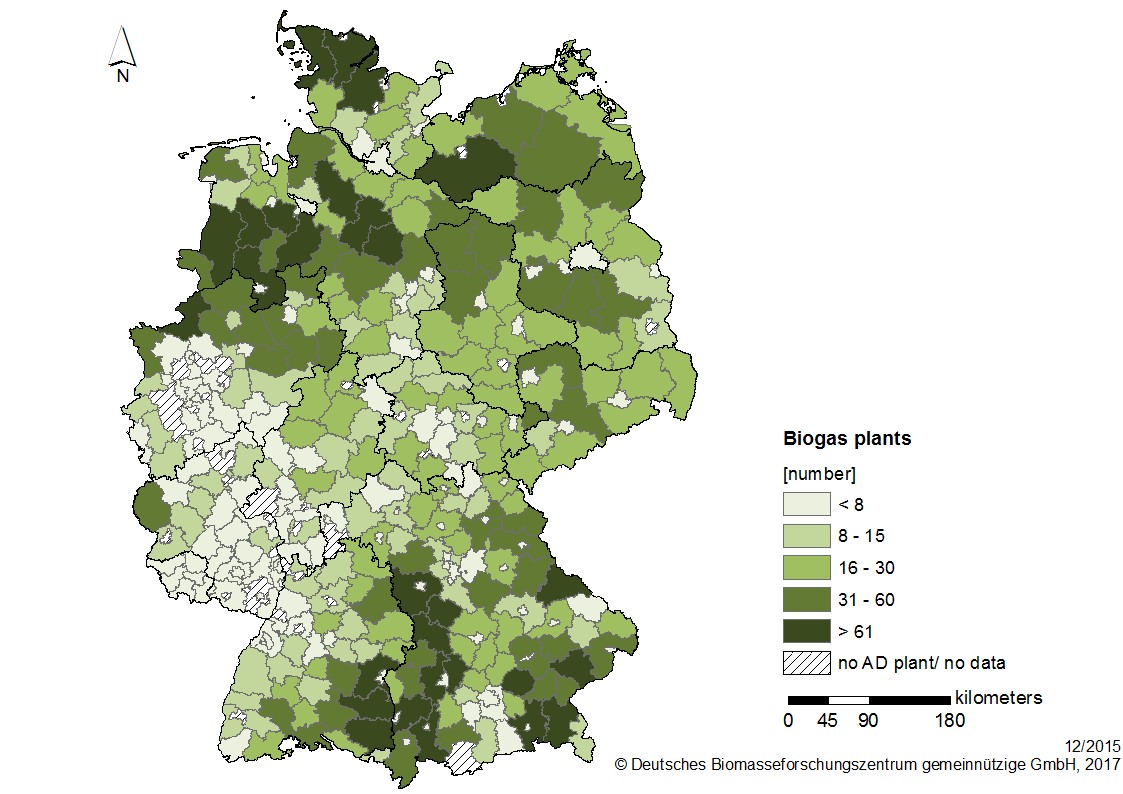

By the end of 2017, about 8,900 biogas production plants incl. upgrading plants for biomethane were in operation. In Germany, biogas plants are operated to a large extent in agricultural sector. See Table 1: Number of biogas production plants in Germany referring to substrate category in 2017.

Type of biogas production plants | Number of biogas plants |

Agricultural biogas plants | app. 8,350 |

thereof manure-based small-scale plants (≤75kW) according to §27b EEG 2012/ §46 EEG 2014/ §44 EEG 2017 | app. 700 |

Biowaste digestion plants (share of organic waste ≥ 90 %) | 137 |

AD plants based on organic waste and manure/ energy crops (share of waste < 90 %) | app. 200 |

Biogas upgrading plants (biomethane) | 200 |

Biogas production plants, total | app. 8,900 |

Energy generation from biogas (without biogas upgrading plants – biomethane) [BMWi (2018) Erneuerbare Energien in Zahlen. Berlin]

- Electricity production from biogas 2017: app. 29,3 TWhel

- Heat supply from biogas 2017: 14 TWhth

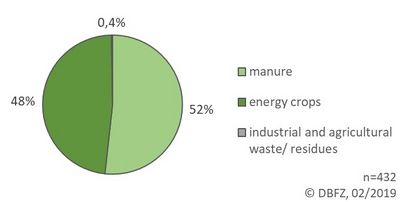

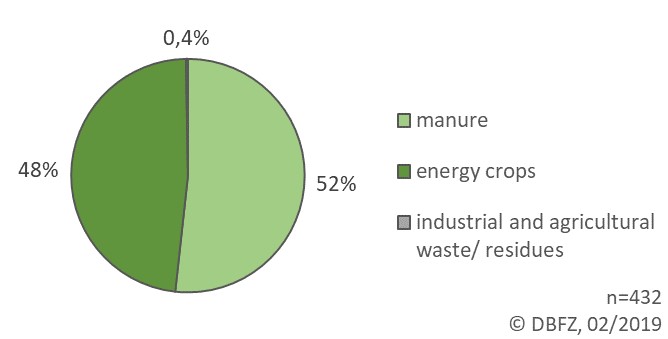

Approximately 8,350 biogas production sites in Germany produce electricity and heat based on slurry/solid manure and renewable resources (agricultural biogas plants). Slurry and solid manure are used in at least 7,600 biogas plants for biogas production and make up a total of about 52% of the use of substrates (based on the quantities used) in agricultural biogas plants. Taking into account the provision of electricity, the use of slurry/ solid manure for 2016 in total can be estimated at around 53 million t (fresh matter). According to initial estimates, this corresponds to about 30% of the available potential.

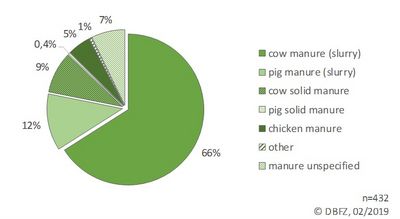

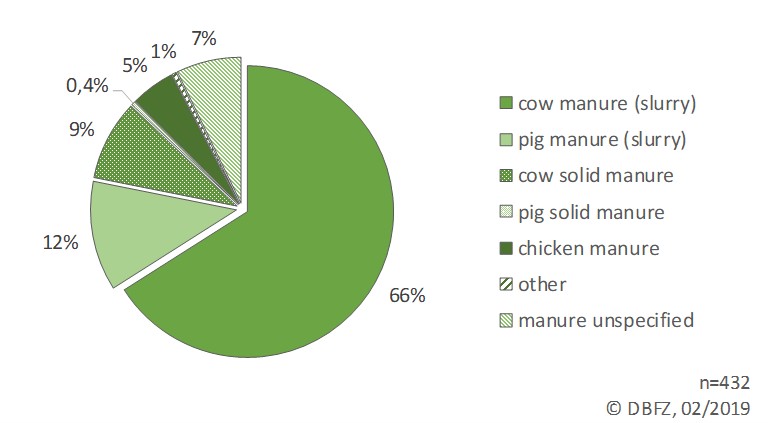

Substrate input in agricultural biogas plants is shown in Figure 2. Manure (solid and liquid) account for about 52 % of the input material in biogas plants. The category “residues” comprises mostly remnant fodder, residues of potato and vegetables, fruit pulp, as well as plant byproducts. Cow manure is by far the main agricultural residue used for biogas production concerning mass content (Figure 3).

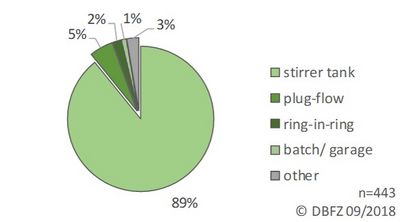

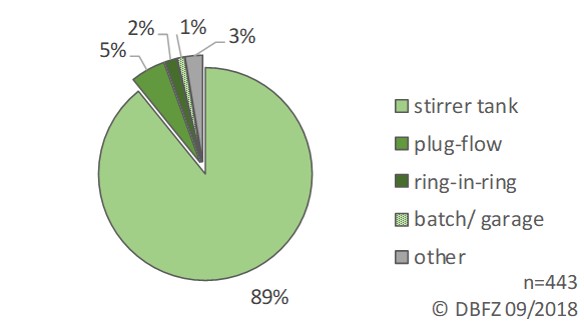

The majority of the biogas plants are operated as wet fermentation with stirrer tanks. The results of the survey show that more than 90 % of the considered plants are operated with this digester system (see Figure 4).

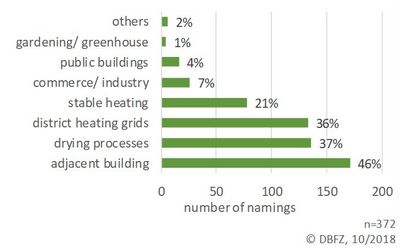

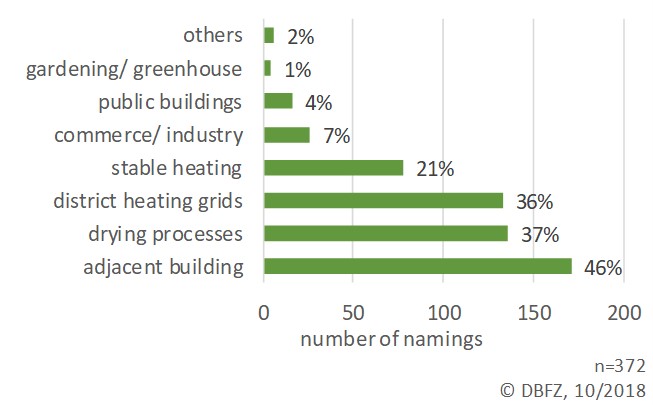

After subtracting the plant’s own heat demand, the majority of biogas plants utilize the heat generated by the CHP externally. On average 56% of the externally available heat were used. The majority of biogas plant operators use the external available heat for heating adjacent buildings. This comprises heating of residential rooms, offices and workshops as well as water heating (46% of biogas plants). About 36 % of biogas plant operators provide their available heat for district heating grids.

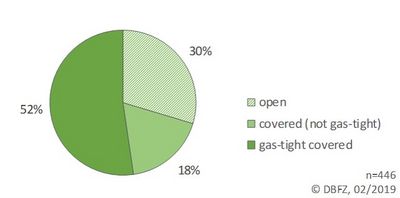

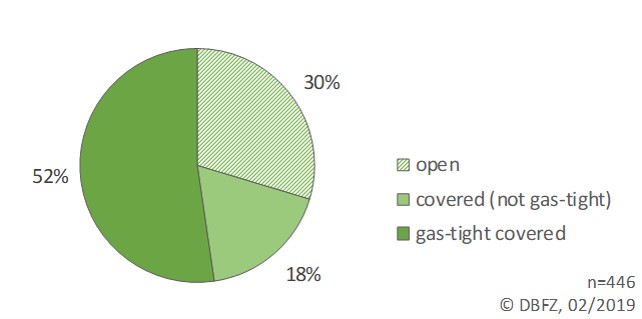

With regard to the total digestate storage capacity (volume based), gas-tight covered storages account for about 52% of digestate storage capacity (Figure 6). About 30 % of digestate storage cpacities are still open without any covering.