Equipment

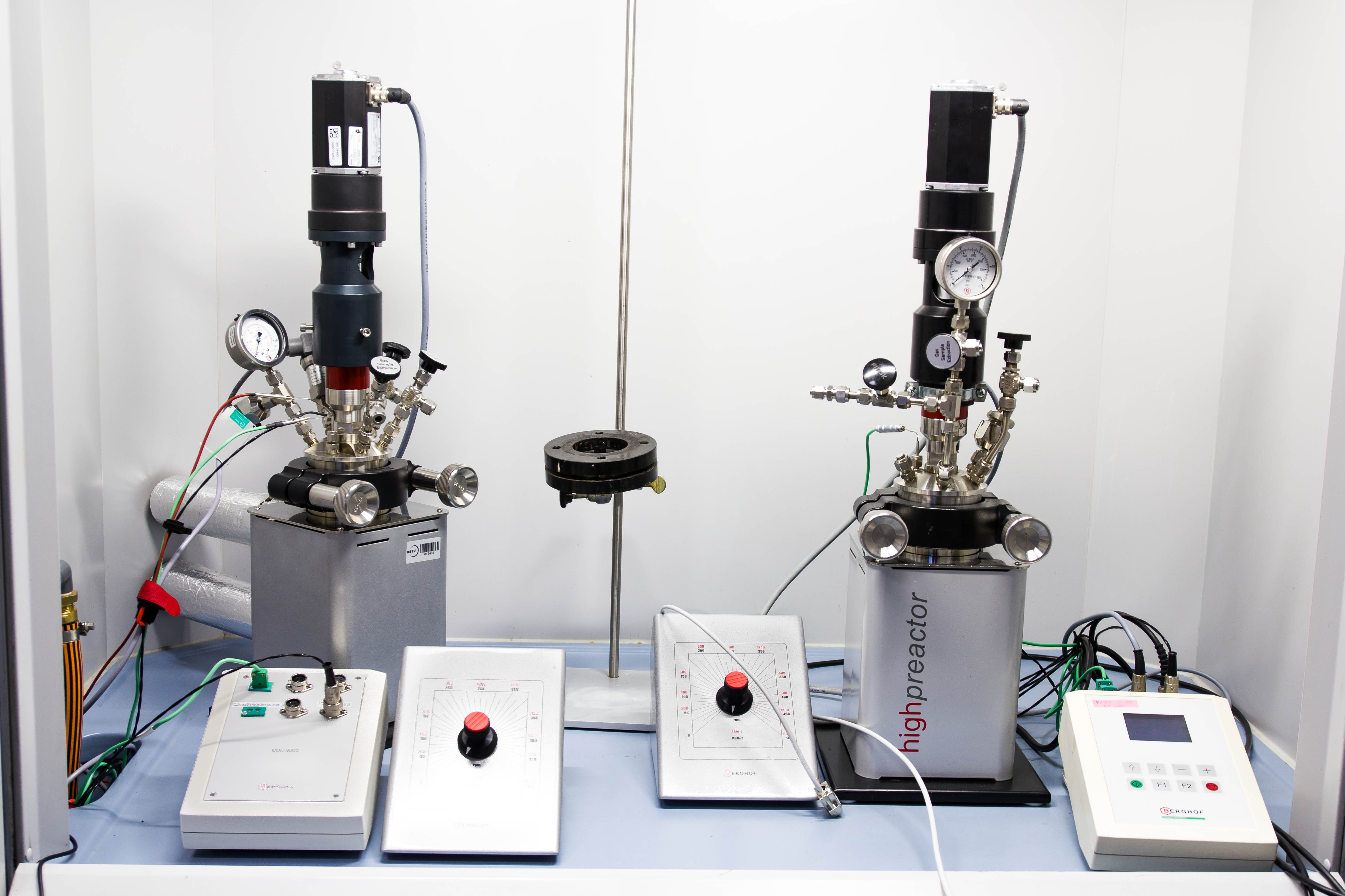

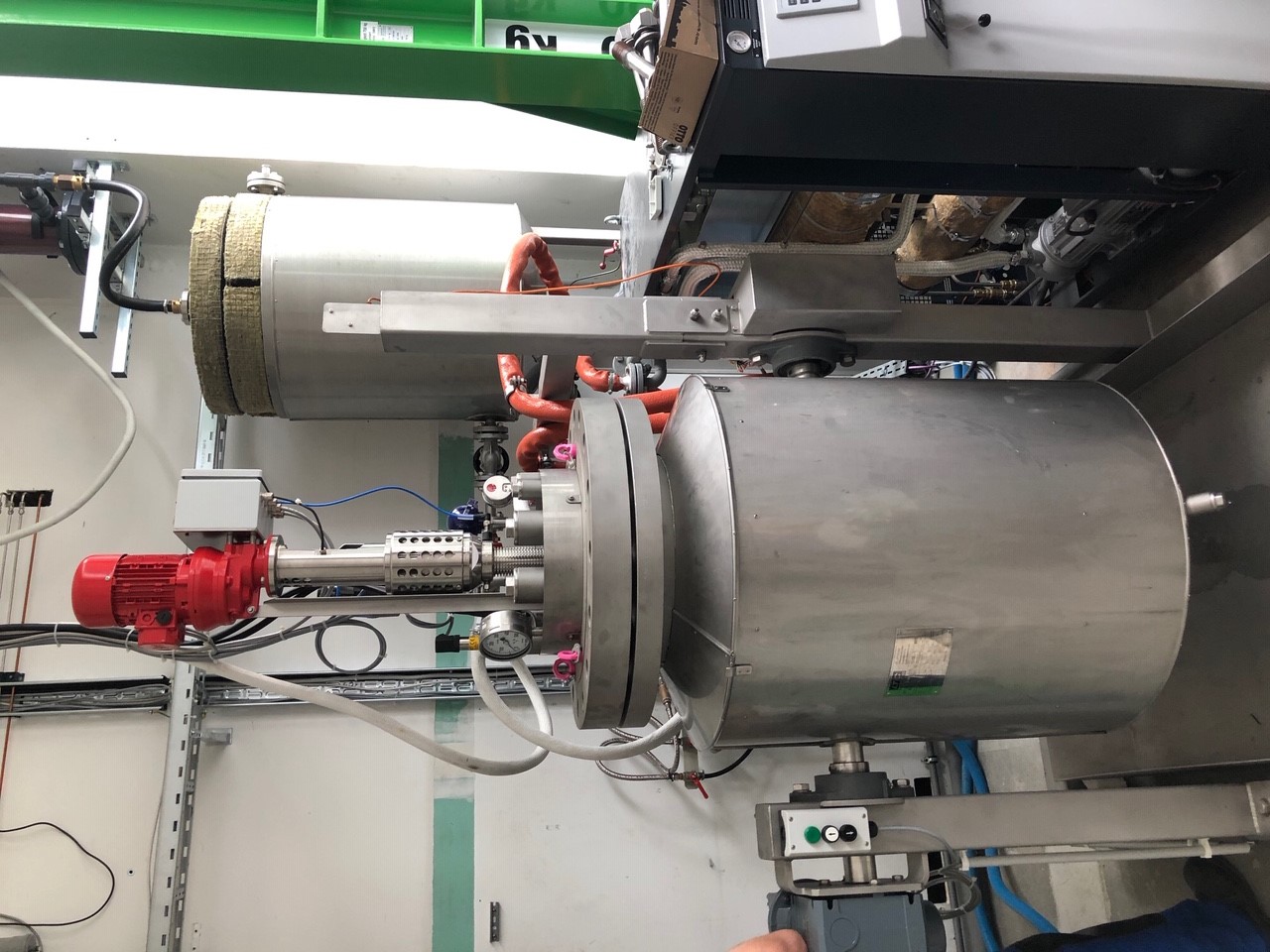

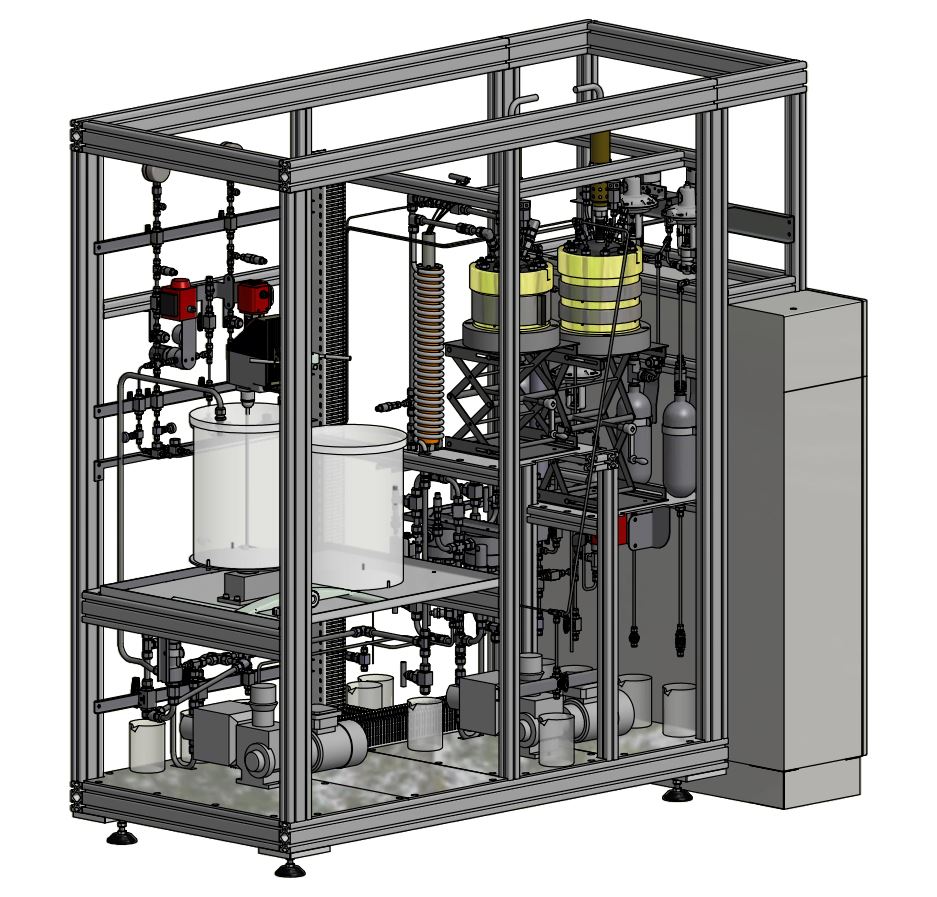

For research and further development on hydrothermal processes, DBFZ operates several autoclaves and experimental set-ups at different scale. Batch reactors have the advantage in processing a wide range of different biomass, usually without pretreatment steps. Besides the discontinuous reactors, DBFZ also operates continuous lab reactors.

electrically heated:

- Tmax = 300 °C, pmax = 200 bar, heating rate: up to 2.4 K min-1

- in-situ-sampling of process water possible

- liquid charging during the process possible

thermal oil heated:

- Tmax = 270 °C, pmax = 200 bar, heating rate: up to 2 K min-1

- in-situ-sampling of process water possible

- liquid charging during the process possible

- fast, active cooling via thermostat possible

- 1st stage (hydrothermal pulping): Tmax = 350 °C, pmax = 200 bar

- 2nd stage (hydrothermal refining): Tmax = 300 °C, pmax = 100 bar

- maximum flow rate 8 L h-1

- sampling after first stage is possible

- 2nd stage equipped with catalyst basket (in-situ-hydrogenation possible)

- 2nd stage can be purged with H2 (100 bar)

Analytics

In order to be able to answer scientific questions concerning hydrothermal processes, DBFZ has its own analytical lab with a wide range of services.