Selected findings of the PaplGas-project (feasibility study)

- The fundamental feasibility of the entire process chain from poplar wood (short rotation coppice) to peat substitute via anaerobic digestion and aerobic post-treatment was demonstrated on a laboratory scale.

- The methane potential of the moist preserved poplar wood fibers in batch tests reached a maximum of 310 mL/gVS or 132 mL/gFM, respectively.

- The type of wood storage, the comminution of the fibers and the inoculation sludge used influence the methane potentials determined in laboratory batch tests.

- The continuous anaerobic digestion of wood fibers with cattle manure was stably possible with the addition of trace elements. The addition of fibers allowed a significant increase in biogas production compared to a sole cattle manure digestion.

- The continuous anaerobic digestion of poplar wood fibers with horn meal instead of cattle manure in stirred tank reactors was stably possible without the addition of further macro or micro elements under the selected conditions. In the period between test day 70 and 240, a methane formation of 162 mL/gVS was determined from poplar wood fibers and horn meal.

- The poplar fibers digested with horn meal and aerobically treated are basically suitable as a component of growing media and potting soils with currently max. 40 vol.% and can contribute to the substitution of peat. Due to the raw materials and the production process, the fibers are also suitable for growing media in organic farming.

- The structure and color of the aerobically post-treated poplar fibers are very interesting from a plant cultivation point of view. In independent tests, the fibers showed low N immobilization and no phytotoxic effects on germination and growth of cress, Chinese cabbage and lettuce at levels of 20 to 40 vol.% in horticultural growing media. They contain plant-available nutrients that can be credited on the usual addition of mineral or organic fertilizers.

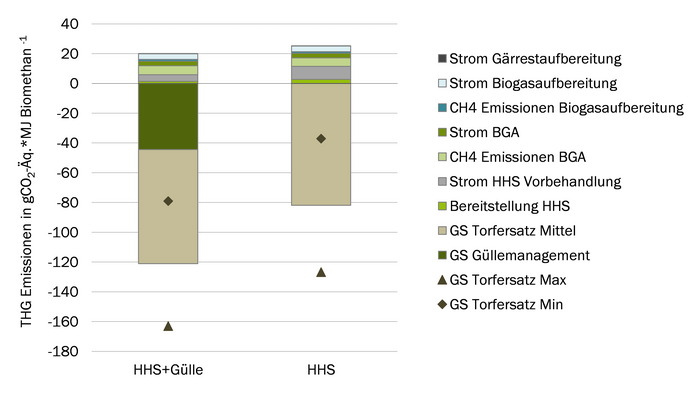

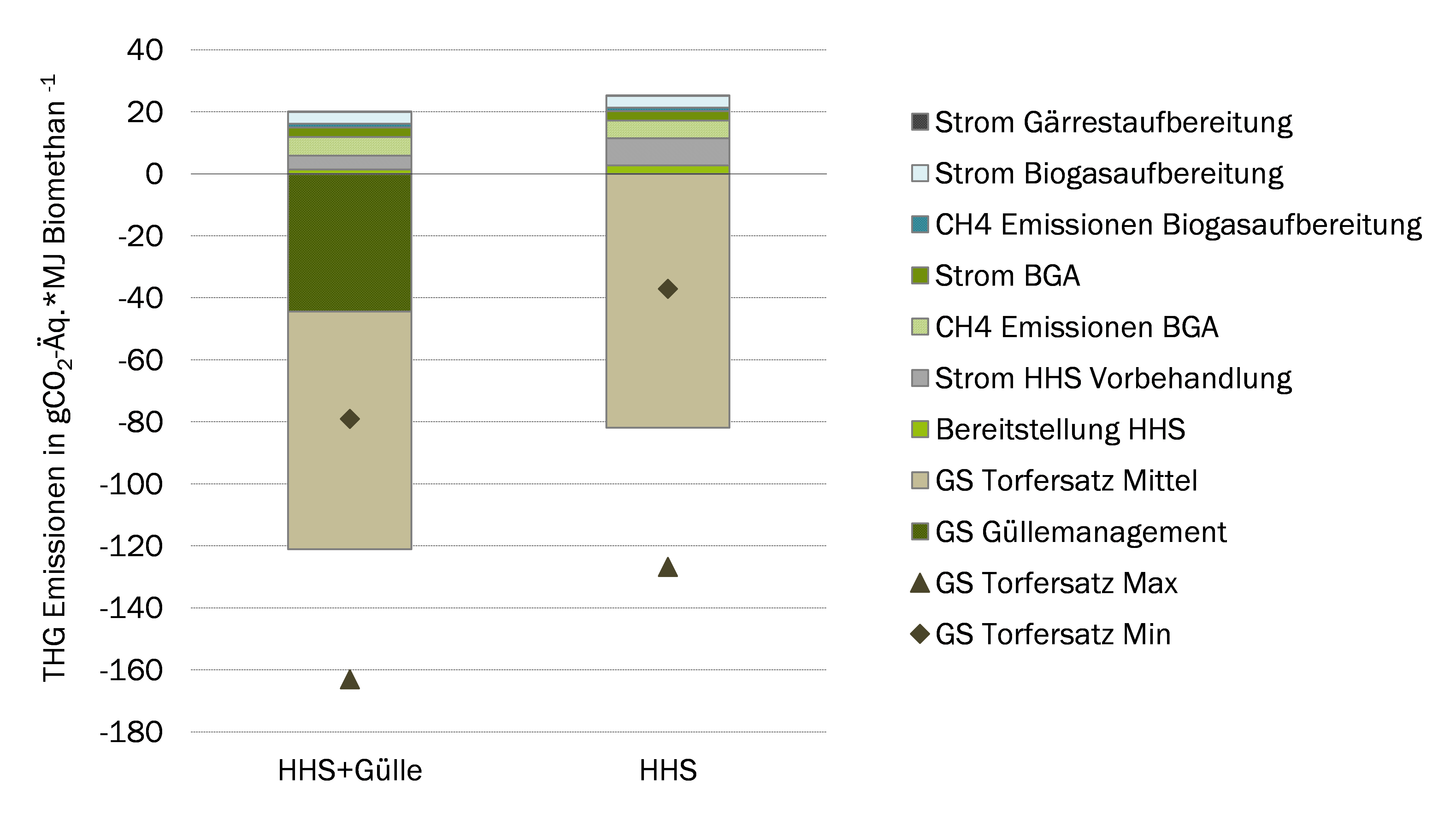

- The short ecological assessment within the feasibility phase showed a reduction in GHG emissions for the selected model process chains for wood fibers in mono-digestion or co-digestion with cattle manure compared to the same biomethane production from maize.

- Taking into account peat substitutes and manure credits, the biomethane production even results in negative emissions with balances of -101 gCO2-eq./MJ (HHS+Gülle) and -57 gCO2-eq./MJ (HHS), see figure. Due to the lower salt content, the application possibilities of peat substitutes from wood fibers from mono-digestion are significantly greater than those from co-digestion with cattle manure.

- A preliminary short economic evaluation within the feasibility phase also revealed a positive balance for the selected model process chains for wood fibers in mono-digestion and co-digestion with cattle manure.

- Further R&D work is needed to achieve higher methane yields on a semi-/technical scale as well as biologically stable peat substitute products.

Greenhouse gas balance (GHG) Wood fiber digestion with or without cattle manure, for further information see final report PaplGas (HHS=wood fibers, GS=credit, BGA=biogas plant, CH4=methane, Strom=electricity)