Working group

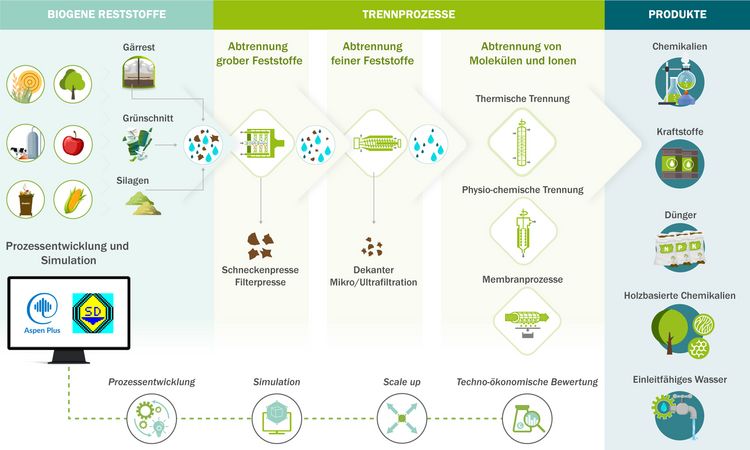

Efficient separation processes are a fundamental component of modern biorefinery concepts for the production of bio-based products and fuels. We design and develop the integration of multiple process steps into complete separation cascades. For investigations, a wide range of industry-relevant separation equipment for solid-liquid and liquid-liquid separations is available. Using process flow simulations mass and energy balances are calculated, which serve as the basis for techno-economic analyses and sustainability assessments.

Focus Areas of the Working Group:

- Solid-liquid separation: Decanters, thermal dewatering, filtration

- Liquid-liquid separation: Membrane filtration, extraction, distillation, evaporation, preparative HPLC

- Development of separation cascades

- Biorefinery design: Process synthesis, process flow simulation, scale-up

- Accounting and techno-economic analysis and assessment

Team

The team of the WG Separation technologies and Process Design consists of the following employees:

| Name | Funktion | Expertise | Links |

| Maria Braune | Research associate | Separation processes, carboxylic acids from anaerobic fermentation, biofuels | LinkedIn, Researchgate |

Marcel Fritzsch | Technician | Supervision of research facilities, execution of process engineering experiments, sample preparation | |

| Arne Gröngröft | Working group leader | Separation processes, bioeconomy, biorefineries, techno-economic assessments | LinkedIn, Researchgate |

| Otto Laufer | Research associate | Separation processes, thermal separation processes | |

| Theresa Menzel | Research associate | Process simulation, process development, biogas and carboxylic acids from anaerobic fermentation | LinkedIn, Researchgate |

| Lilli Sophia Röder | Research associate | Techno-economic evaluation, process simulation, demand-side management | LinkedIn, Researchgate |

| Lukas Odenwald | Research associate | Separation process, digestate treatment | LinkedIn, Researchgate |

| Bomin Yuan | Research associate | Digestate treatment, carboxylic acids from anaerobic fermentation, separation processes, process simulation | Researchgate |