Separation technologies

In the biorefinery lab, separation processes can be developed on a laboratory and pilot scale. Parameter studies and process optimisations can be carried out on a small scale with small amounts of feedstock. Samples can be prepared at pilot plants and experience can be gained with equipment in continuous and near-industrial operating environments.

Filter press

Dewatering of sludges

- Up to 12 bar

- Filtration area: 6 m²

- Volume per batch: 75 L

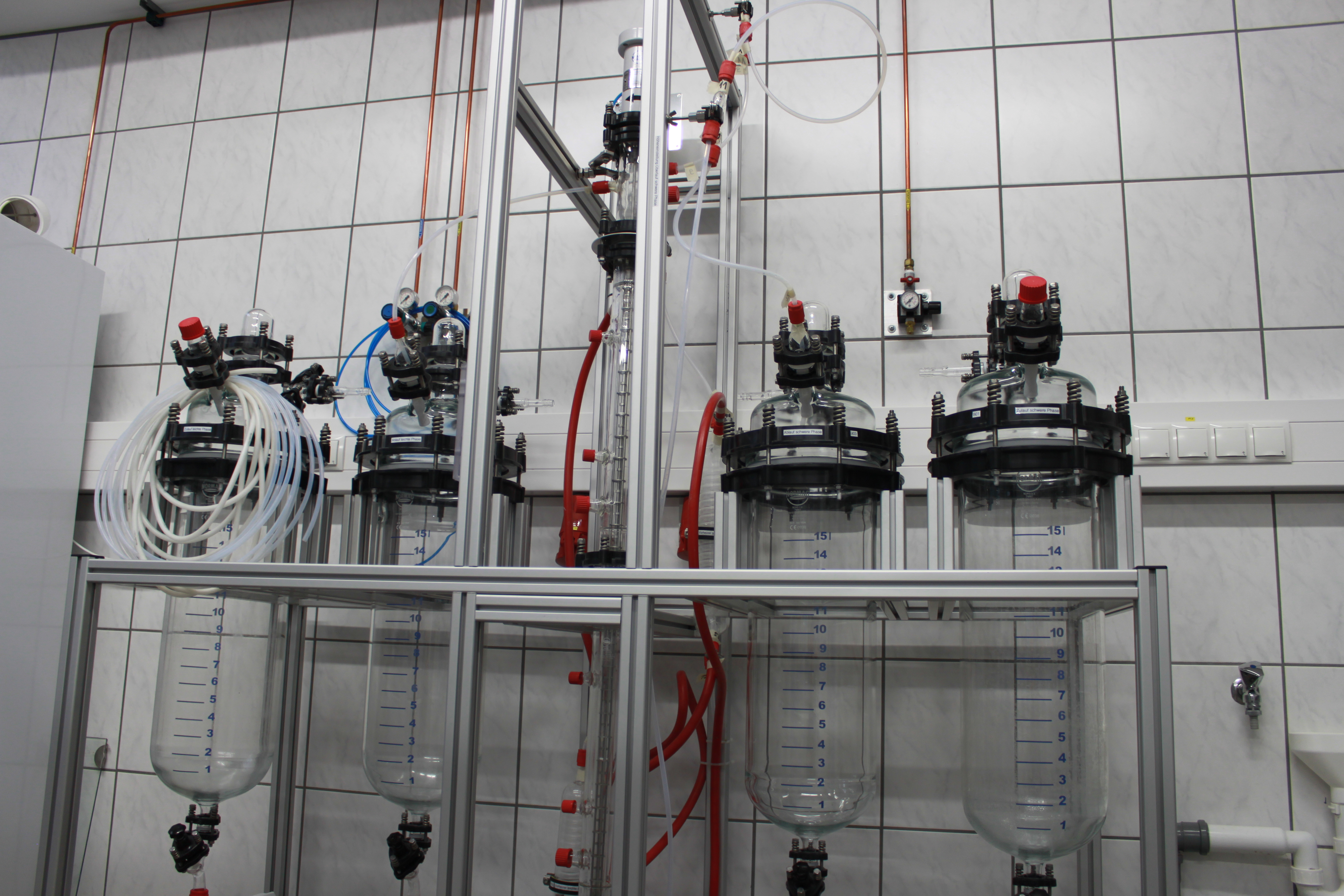

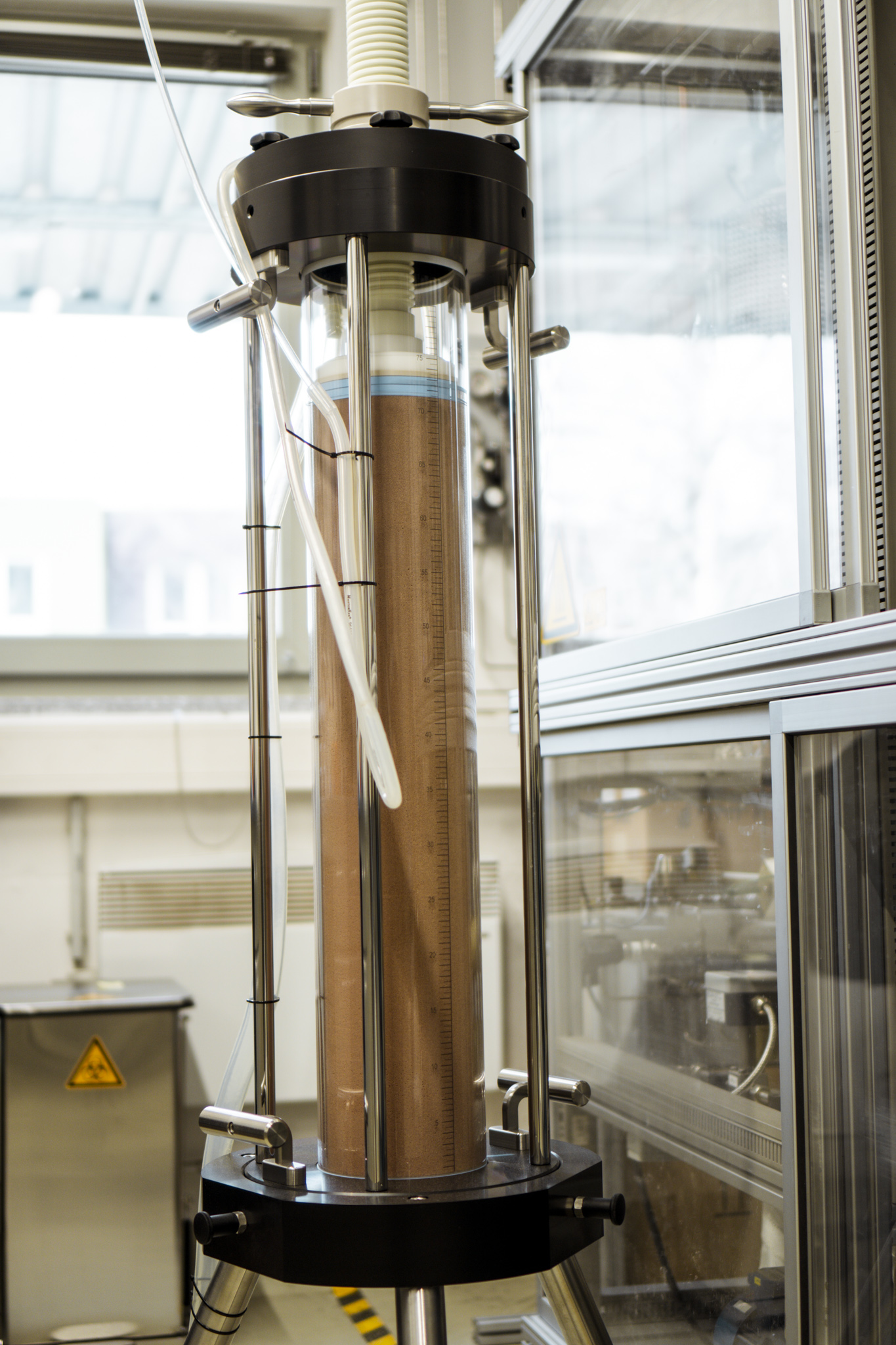

Membrane filtration

Different cross-flow filtration units for microfiltration, ultrafiltration, nanofiltration and reverse osmosis in different sizes:

- Polymeric flat sheet membranes

- Spiral wound membranes

- Ceramic membranes

Dead-end membrane filtration for membrane screening and characterization

Forward osmosis test unit for gentle and energy-saving dewatering

- Flat sheet membranes

- Membrane area: 42 cm²

- Online conductivity measurement