Technical equipment

DBFZ operates several pilot plants for research into and further development of hydrothermal processes. Batch autoclaves, which treat biomass or biogenic residues in defined amounts, have the advantage of processing a wide range of starting materials directly, largely without additional pre-treatment. DBFZ also has test facilities for continuous or uninterrupted operation. In addition to the classic testing, suitable economic assessments are also carried out.

smallest-scale batch autoclaves for basic experiments with extremely high reproducibility and high parallelisation

- Vmax = 2 mL

- Tmax = 200 °C, pmax = 100 bar (at maximum temperature)

- heating rate: up to 45 K/min

- material: 1.4571 stainless steel (PTFE-inlays available)

- agitation of the contents by magnetic stirring

- individual gas pressurisation possible

small batch autoclaves for small-scale experiments with a very high heating rate thanks to external heating with a fluidised sand thermostat

- Vmax = 20 mL

- Tmax = 360 °C, pmax = 214 bar (at maximum temperature)

- heating rate: up to 60 K/min

- material: 1.4571 stainless steel

- agitation of the autoclave contents possible using an external drive

batch autoclaves for carrying out small-scale, stirred experiments

electrically heated (on the right):

- Vmax = 500 mL

- Tmax = 300 °C, pmax = 200 bar (at maximum temperature)

- heating rate: up to 2,4 K/min

- material: 1.4571 stainless steel (PTFE-inlay available)

- allows for an in-situ-sampling of process liquids

- allows for the dosing of liquid media during the process

heated with thermal oil (on the left):

- Vmax = 500 mL

- Tmax = 270 °C, pmax = 200 bar (at maximum temperature)

- heating rate: up to 2 K/min

- material: 1.4571 stainless steel (PTFE-inlay available)

- allows for an in-situ-sampling of process liquids

- allows for the dosing of liquid media during the process

- fast and active cooling possible

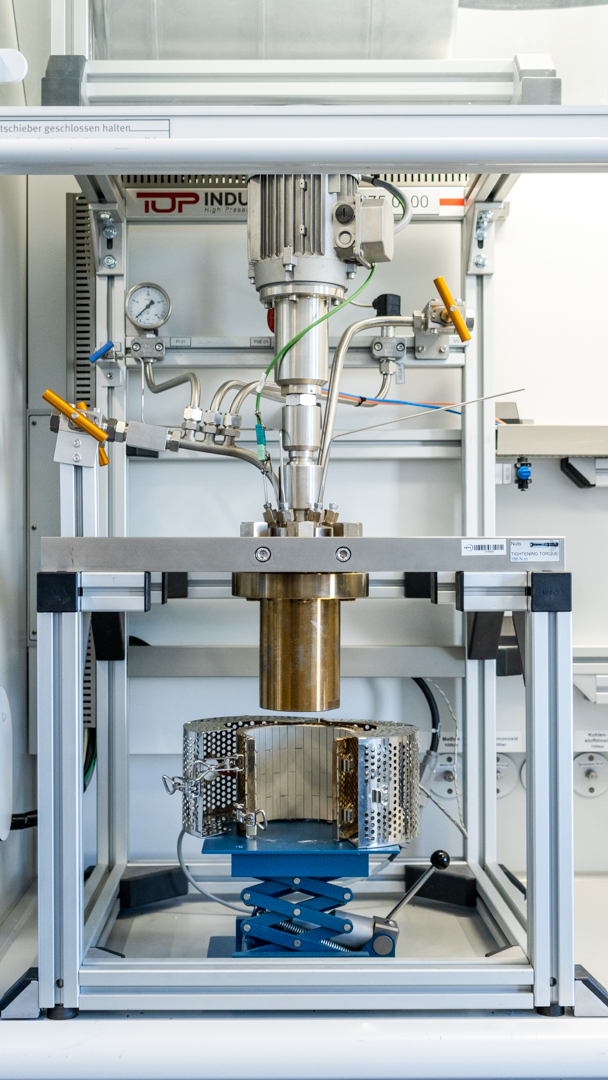

batch autoclave for carrying out small-scale, stirred HTL experiments with a high heating rate using external electrical heating

- Vmax = 500 mL

- Tmax = 400 °C, pmax = 300 bar (at maximum temperature)

- heating rate: up to 10 K/min

- material: 1.4980 stainless steel

- allows for gassing of the reaction medium during the process

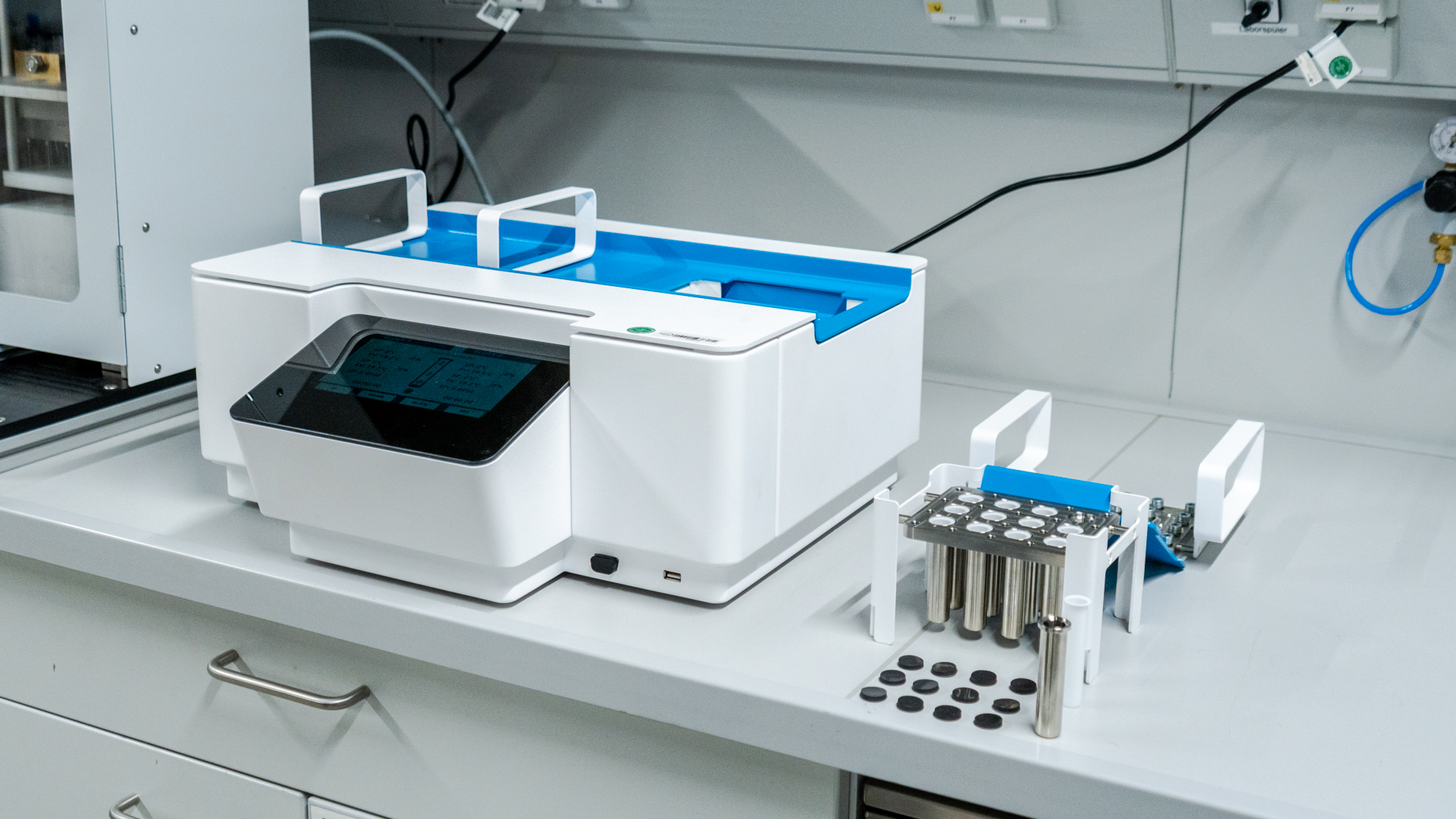

electrically heated batch autoclaves for carrying out small-scale, stirred experiments

- Vmax = 1x 500 mL, 3x 1.000 mL, 1x 2.000 mL

- Tmax = 280 °C, pmax = 150 bar (at maximum temperature)

- heating rate: up to 2 K/min

- material: 1.4404 stainless steel

- allows for in-situ-sampling

- allows for the dosing of liquid media during the process

- parallel operation of up to three autoclaves

small-scale, agitated batch autoclave heated with thermal oil on a 10-litre scale for initial scaling

- Vmax = approx. 8 L

- Tmax = 280 °C, pmax = 100 bar (at maximum temperature)

- heating rate: up to 2 K/min

- material: 1.4571 stainless steel

- fast and active cooling possible

- modular expandability through lid holes and base outlet

- gas sampling from headspace possible

small-scale, agitated batch autoclave heated with thermal oil on a scale of 100 litres for extended scaling

- Vmax = approx. 80 L

- Tmax = 250 °C, pmax = 55 bar (at maximum temperature)

- heating rate: up to 2 K/min

- material: 1.4571 stainless steel

- fast and active cooling possible

- modular expandability through lid holes and base outlet

- gas sampling from headspace possible

technical, agitated batch autoclave heated with thermal oil on a 500 litre scale for the production of large product batches

- Vmax = approx. 500 L

- Tmax = 240 °C, pmax = 40 bar (at maximum temperature)

- heating rate: up to 2 K/min

- material: 1.4571 stainless steel

- fast and active cooling possible

- additional heating and pressurisation with steam possible

- powerful, near-wall agitator (Mmax = 8.000 Nm)

continuous plug-flow reactor for hydrothermal reaction conditions

- VR = 1.100 mL (l = 860 mm, di = 20 mm)

- Tmax = 350 °C, pmax = 200 bar (at maximum temperature)

- material: 1.4571 stainless steel

- flow rate can be varied in the range of 0,6–8 L/h

- only suitable for use with liquid media or slurries with particles < 1.5 mm

Analytics

DBFZ operates its own analytical laboratory with a correspondingly wide range of services to provide the best possible answers to scientific questions relating to hydrothermal processes.