Technical Infrastructure

The Apeli Stove

APELI stove, meaning “cooker which preserves the household and the environment” in the local language is developed within the framework of LabTogo project, funded by BMBF, based on the needs of the locals in Togo. APELI is a forced-draft cookstove with three main parts: an outlet made of ceramic, an inlet made mainly of a recycled can and a fan. The stove was tested based on the ISO 19867-1:2018 standard and the results showed that the APELI would correspond to Tier 4 for efficiency and PM 2.5 as well as Tier 5 for CO in high-power operation using wood pellets. The use of alternative fuels is possible, but can lead to higher emissions compared to the use of wood pellets. More information can be found here or you can contact with Dr. Dennis Krüger (Contact)

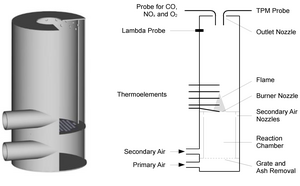

Lab-scale TLUD burner

Our small-scale biomass burner (4.7 kWfuel) operates based on "top-lit updraft" (TLUD) principle. Briefly, the fuel is ignited from the top using a fire starter and begins to burn by releasing gases. Primary air flows upwards within the combustion chamber, while black char starts to accumulate at the top and hot pyrolytic front moves downward through the solid mass of raw biomass by converting it into char. Once the combustion of the pyrolytic gases is completed, the yellow flame turns to blue indicating that the so-called "char burn" phase starts. At the end of the process, remaining char with higher calorific value can be utilized in different applications such as fuel in cookstoves to reduce indoor air pollution and deforestation or as soil enhancers in soil applications to improve soil pH, nutrient availability, moisture, and organic matter. TLUD technology is mostly used for cooking purposes in many parts of the world and is known for its ability to release lower emissions and PMs as well as being fuel-flexible. More information can be found here

Muffle Oven

The tailor-made biochar production process is conducted in a laboratory-scale chamber furnace (CWF 12/23) from Carbolite Gero GmbH & Co. KG, which has been modified with a retort to enable the generation of a controlled atmosphere. The furnace is capable of reaching temperatures up to 1100 °C. It is equipped with a temperature sensor that allows for the implementation of pre-established heating programs with varying heating rates and residence times. The creation of inert conditions is facilitated through the supply of nitrogen. Furthermore, another additional gas supply can be integrated to generate specified heat treatment atmosphere (Contact)

Kitchen: Testing cookstoves under real conditions

In our department, Thermochemical Conversion, we develop variety of cookstoves for different purposes and regions. Thus, these cookstoves are needed to be tested based on different criteria such as emissions, performance, safety and durability. Most of the cookstoves in the literature are tested only under lab conditions, yet they do not reflect the results under real-life conditions. We have a fully equipped (i.e. water, electricity), so-called “Kitchen” for testing our developed biomass cookstoves under real cooking conditions. The Kitchen was funded within the framework of ETH-Soil project. For more information, please contact Dr. Dennis Krüger (Contact)

Analytical lab

For the characterization of biomass and biochar, DBFZ has fully equipped analytical lab. offering wide-range of analyses. More information can be found here

The offer of the analytical laboratory is extended by the following analytical measuring devices which are maintained by the members of the working group:

STA-FTIR-MS Coupled with NETZSCH STA 449 F3 Jupiter®

The simultaneous application of thermogravimetry and differential scanning calorimetry to a single sample provides a great gain in information compared to an application in two different devices:

- The test conditions are completely identical for the TG and DSC signals (atmosphere, flow rate, vapor pressure above the sample, heating rate, thermal contact, radiation effects, etc).

- The evaluability of the signals is improved, as two or more pieces of information on the sample behavior are always available simultaneously (differentiation of phase transformations and decompositions, of addition and condensation reactions, of pyrolysis, oxidation and combustion reactions, etc.).

- Emission gas analysis (EGA) has already established itself as an important tool for clarifying the chemical and physical relationships between the processes to be investigated in organic and inorganic solids, liquids and polymers.This is made possible by the coupling of the FT-IR spectrometer from Bruker Optik and 403 Aëolos® quadrupole mass spectrometers.

For further information, please contact with Dr. Andreas Schedl (Contact)

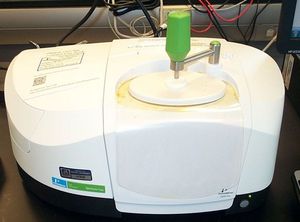

Perkin Elmer Spectrum Two Fourier Transform Infrared (FTIR) Spectrometer

We also use a Perkin Elmer Spectrum Two Fourier Transform Infrared (FTIR) spectrometer with transmission and attenuated total reflectance (ATR) modules to support its materials analysis capabilities, for biomass and biochar characterization. In the ATR technique, a liquid or solid is placed on a diamond crystal and exposed to an infrared beam over a wavelength range of typically 2.5-25 μm (wavenumber range 4000-400 cm-1), which penetrates the diamond crystal and forms a decaying wave that penetrates and reflects off the surface of the sample. Infrared light is absorbed or emitted depending on the chemical bonding in the material, and the spectral fingerprints subsequently generated can be used to determine the material composition. For further infomration, please contact to Dr. Andreas Schedl (Contact)