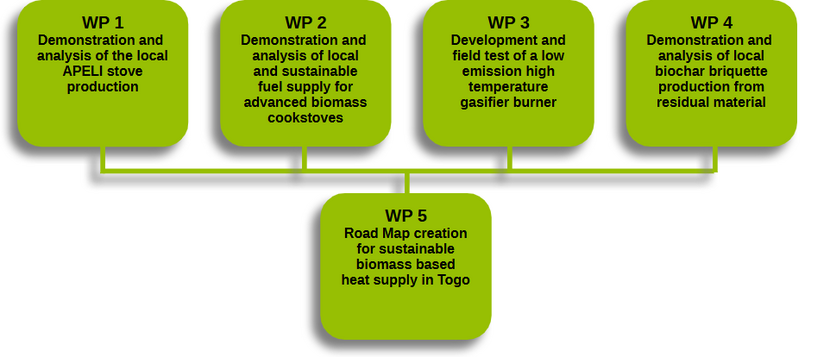

Work Packages

The HeRoTogo project was divided into 5 work packages. Four of the five work packages serve to test, optimize, and evaluate the proposed technologies and processes for heat generation, while all research results will be synthesized in the fifth work package. In other words, the four technical work packages will provide a data basis for imformed conclusions and recommendations which will be summarized in the desired road map. The project's structure can therefore be depicted as follows:

Work package 1: Demonstration and analysis of the local APELI stove production

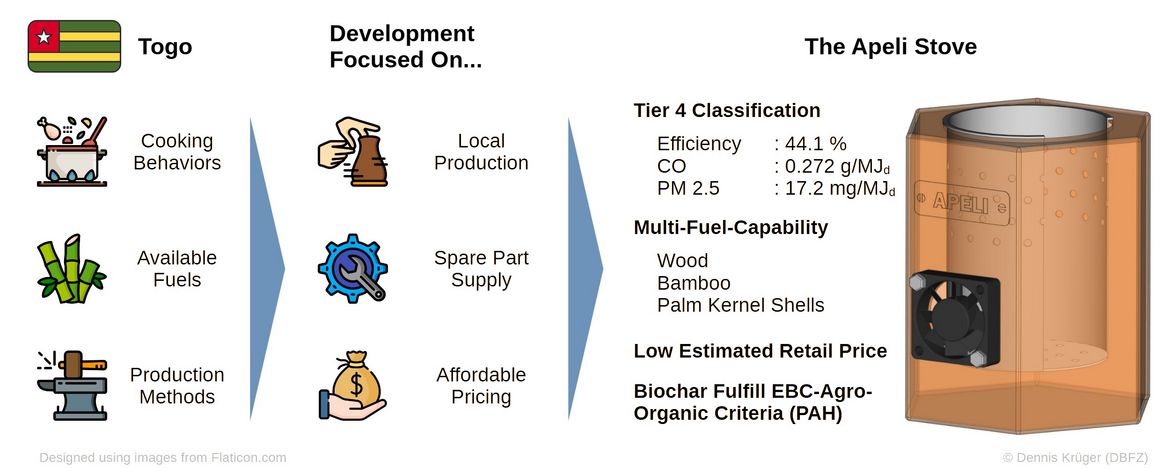

Work package 1 focuses on demonstrating the local production of the APELI biomass cookstove, which was developed during the LabTogo project (WASCAL-DBFZ). For this purpose, the manufacturing process will be set up at at least two locations under real-life conditions. The entire manufacturing, maintenance, and sales structure will be tested and evaluated with regard to future mass production, as well as further technical optimization of production based on the producers' practical experience and expertise. Finally, based on this data, a robust business model for the mass production of the APELI biomass cookstove will be generated. Furthermore, the work package includes the identification of barriers, which, if weakened or completely eliminated (e.g. through cooperation with state actors), could lead to easier and faster market entrance.

Krüger, D.; Mutlu, Ö. The Apeli: An Affordable, Low-Emission and Fuel-Flexible Tier 4 Advanced Biomass Cookstove. Energies 2023, 16, 3278. https://doi.org/10.3390/en16073278

Work package 2: Demonstration and analysis of local and sustainable fuel supply for advanced biomass cookstoves

The APELI is a very efficient and low-emission biomass cook stove. However, it requires well-defined fuel to guarantee consistent results and user-friendliness. In work package 2, the production of a variety of fuels from locally available biomass and residues will be locally demonstrated. The findings will be integrated into the "APELI" business model. Depending on the location and available biomass, the fuel production will be carried out either purely mechanically or by using manually operated machines for decentralized fuel production and automated ones for central fuel production. Potential customer groups will test the fuels for their operability, suitability and overall attractiveness.

Work package 3: Development and field test of a low emission high temperature gasifier burner

The body of the APELI biomass cookstove is made of ceramic, which must be fired on-site at appropriately high temperatures. To date, large, inefficient kilns have been used to fire ceramics in Togo, which also use large amounts of wood as fuel. Work package 3 therefore aims at the development, testing, and process integration of a low-emission pyrolytic high-temperature burner for the local production of these ceramic elements- Similar to the "APELI"-stove, the high-temperature burner shall be operated with existing biomass residues as fuel. In addition to the efficient and low-emission generation of correspondingly high temperatures, the work package also includes the development of inexpensive ceramic-based insulating materials made from local raw materials. Since the burner required for this purpose must achieve a certain output, it represents all sustainable, commercial heat generation, which usually operates at significantly lower temperature levels (e.g. cooking, baking, roasting, drying, etc.).

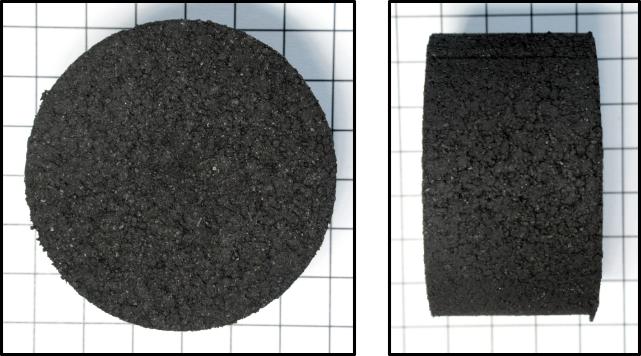

Work package 4: Demonstration and analysis of local biochar briquette production from residual material

Much of the cooking energy in Togo is currently provided by charcoal. The production is based primarily on unsustainable logging and inefficient charring techniques with low yields and high emissions. In work package 4, a system for combined biochar production and briquetting for fuel production will be developed and tested on site. Currently unused local biomass residue streams will be used as input materials. The goal is to replace charcoal as far as possible with sustainable production of biochar fuels. The fuels produced will be evaluated by the users in terms of suitability and price. The target group's feedback is crucial to analyze and optimize the production process and to develop a suitable business model.

Work package 5: Road map creation for sustainable biomass based heat supply in Togo

Work package 5 brings together the findings of the 4 technical work packages from e.g. surveys, studies, bachelor's or master's theses. Based on this input data and the tested technologies, a roadmap will be developed that presents sustainable solutions for the local use of biomass in heat generation. A particular focus will be placed on domestic heat generation for food preparation and the commercial sector for providing process heat for various applications.